A Davis startup has built a device to harvest waste metal in orbit, and then use it to build components in space.

Build Beyond LLC has received two grants from NASA for its technology to recycle metal in orbit, CEO Graham Ryland told the Business Journal.

"A tremendous amount of value is locked up in the tons of aluminum in orbit," he said.

Much of that value isn't in the aluminum itself, but it is in its location, as it's already in space. Bringing materials into space is challenging, as anything brought into space must fit in the nosecone of a rocket.

Build Beyond built its device to capture, harvest and then create metal structures autonomously in orbit.

The company recently got a patent on its process, and it has been invited to participate in the Creative Destruction Lab, a Toronto-based nonprofit group that runs programs for massively scalable seed-stage companies working in science and technology. Build Beyond is exploring the opportunity to redeploy thousands of tons material already in space.

The 2020 startup is founded by Ryland, who is also the co-founder and former CEO of educational robot company Barobo Inc., and John Shepard, who has a doctorate in mechanical engineering. The company's former name was Yolo Robotics LLC.

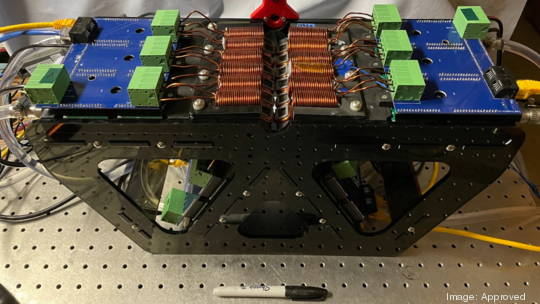

The device they built is about the size of a toaster oven. It uses arrays of independently controlled electromagnets. The magnets can touchlessly capture, move, melt and then form any conductive material into end-use parts.

The system works on steel, aluminum and other metals, which are floating around in low-earth orbit, Ryland said.

The system will likely be used as an inductive foundry in space to make rods, plates, struts and other components to build larger structures in space.

Build Beyond so far has been funded by the Phase 1 and Phase 2 grants from NASA totaling around $875,000. The first grant was to test the viability of the idea, and the second was to build a prototype, Ryland said. Build Beyond is planning to test the device on a NASA zero-gravity testing plane later this year.

While the company was started for recycling space junk, the technology has terrestrial applications, Ryland said. The inductive welding it can do doesn't create sparks, so it can be used in pipeline, railroad and large container applications to weld pieces or mend cracks.

The device is remote, autonomous and has no moving parts. It just needs electricity. The demonstration device they built fits on a table, but the technology is able to scale up to much larger sizes, and it gets more efficient as it scales up, Ryland said.

Build Beyond is still small. It has three employees and another three contract employees. It also doesn't have any ride into orbit yet.

"We will definitely need to work with partners," Ryland said.

There should be interest in the technology, Ryland said, because going into the future, anything put into space needs to have a de-orbiting plan. Usually, de-orbiting now is having pieces burn up as they enter the atmosphere.

Recycling and reuse is "a better alternative to burning up valuable-end-of-life equipment in the atmosphere," Ryland said.

The 24-year-old International Space Station, which is nearly 1 million pounds of equipment, is set to retire in 2031. It would be better to harvest the materials from the space station in the future rather than have bits and pieces of it burn up in the atmosphere, Ryland said.

The Build Beyond device is touchless, and has no moving parts or consumables.

A permanent magnet doesn't work on aluminum, but the electromagnet that Build Beyond developed puts a charge into the aluminum. It then can attract or repel the charged metal. The electromagnet also can heat the metal to melting, Ryland said.