An MIT spinout that uses molten salt to capture carbon in manufacturing has received $30 million in new venture capital.

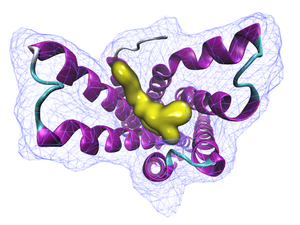

Mantel uses borate, an alkalized salt that integrates into carbon-heavy manufacturing processes. The borate turns into a liquid at high heat and chemically bonds to carbon and other chemicals, reducing the carbon from industrial manufacturing output by up to 95%, according to the company.

With its new Series A investment, the carbon-capture startup plans to scale up the design of its product and move from “lab success,” as Halliday calls it, to building site demonstration projects.

Halliday is also looking to expand its Cambridge-based team, which has grown rapidly from three people in 2021 to over 24 in 2024. Mantel is looking to fill positions for commissioning engineers who work on-site, deploy and run the system.

According to Cameron Halliday, CEO and co-founder of Mantel, people have researched approaches to high-heat carbon capture for over 20 years. The concept works well on paper, but when put into intense high-heat environments, many methods would rapidly degrade and need to be replaced frequently.

- Sign up for The Beat, BostInno’s free daily innovation newsletter. See past examples here.

Halliday and his co-founders were looking to improve this degradation problem from high-heat carbon capture when the scientific process and a little luck provided them with an "a-ha" moment.

“We were never expecting to solve the problem. We were expecting to improve it. But this completely solved the problem,” said Halliday.

Molten borate to capture carbon

The reason molten borate works so well, according to Halliday, is because it can just keep going. The salt melts down and can be recycled into the system while extracting up to 95% of the carbon emissions, he said.

When integrated into a high-heat environment, borate doesn’t degrade as quickly as other materials used for carbon capture.

“In some ways, you're fighting fire with fire. They are very aggressive materials, which makes them challenging to work with, but it also makes them challenging to break. So they don't suffer from the same kind of degradation mechanisms that other chemistries are plagued by,” said Halliday.

Whereas borate has a high threshold to withstand degradation compared to other carbon capture solutions, it still risks contamination. However, if the salts are in an environment that’s predominantly carbon dioxide, nitrogen, oxygen, and moisture, Halliday says the molten borate can run indefinitely.

The borate is made from commodity materials that are widely available and have a large global production market, making it easy to produce and distribute.

“Carbon capture has been a lot of a lot of talk and a lot of design studies for a long time, and we need to see these technologies being deployed to have a real impact. We're excited to get this technology scaled up and deployed in industry and have a true impact on our climate goals,” said Halliday.