A Cambridge-based startup that recovers critical metals from mining and factory operations has closed its seed round with a total of $11.8 million led by the sustainability-focused VC firm 2150, with participation from several other ventures.

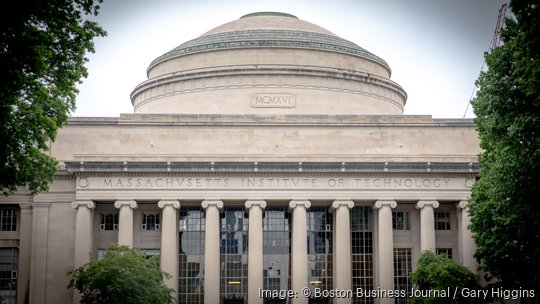

Brendan Smith and Jeffrey Grossman founded SiTration at MIT during their doctorate and postdoctoral work in 2014. SiTration uses an electrified silicone filtration system to reclaim metals like copper, cobalt, and lithium-ion.

According to Smith, the startup's CEO, the system aims to create a durable, cleanable filter with the most significant financial, economic, societal, and environmental impact.

The $11.8 million in seed funding allows SiTration to take its silicon-based filtration system out of the lab and into the field. The startup has been developing and testing its systems with commercial feed material. It can now deploy a scaled-up system on-site at mining companies and lithium-ion battery recyclers.

“What that’s going to unlock, within one to two years from now, is larger commercial contracts and much more scaling up of the technology to go on commercial sale,” said Smith.

Traditional filtration systems are made of ceramic or polymeric membranes, which can get clogged quickly and be hard to clean. Additionally, the cleaning process for existing filters can quickly degrade the material, causing a high filter turnover.

SiTrations silicon filter not only provides higher durability because it can withstand harsh chemical cleaners, but according to Smith, it can also filter better and more selectively.

The systems have yet to be used commercially, but Smith and his team project a minimum lifetime of three years, with higher estimates between five and 10.

According to Smith, a process known as electro-extraction involves applying a voltage to the filtration membrane, which amplifies the membrane's selectivity and performance.

In addition to extracting the critical metals, the process also yields “relatively clean water” that can be recycled by mining companies, released back into the environment, or used for agriculture.

“You’re actually effectively reducing the amount of volume of waste that’s produced in addition to being able to capture those valuable things out very selectively,” said Smith.

The SiTration process also boasts a reduction of emissions. Cultivating critical metals involves industrial heat and a large degree of chemical inputs. SiTration aims to take these processes and convert them into electrification instead.

“We predict that we can reduce the amount of chemical and energy consumption by 75% to 90%,” said Smith.