A College Park company creating a new type of wood with the strength of steel has leased an 88,971-square-foot manufacturing facility in Frederick, Maryland.

InventWood plans to move into its 5971 Jefferson Station Court headquarters by early March thanks to a $20 million grant from a U.S. Department of Energy program. The company will use the facility to start manufacturing its flagship product MettleWood in early 2025 and hire at least 50 to 60 employees.

InventWood is currently located at the University of Maryland, College Park, where founder Liangbing Hu conducted most of the early research into how to turn normal wood into an strong construction material.

InventWood needs the new facility because the Department of Energy wants it to be able to manufacture 1 million square feet of MettleWood each year. CEO Josh Cable said he chose Frederick because of the access to transportation, a large labor supply and the ability to easily get wood into the factory from logging operations in Western Maryland and other rural areas.

Kristin Rebeck, of Towson-based KLNB, represented InventWood in the lease transaction with Lincoln Property Co. and noted that InventWood's needs changed massively when it got the ARPA-E grant. The company went from looking for around 17,000 square feet to 88,000 square feet overnight. Brent Prossner and Kyle Bell of Lincoln Property represented the landlord in the deal.

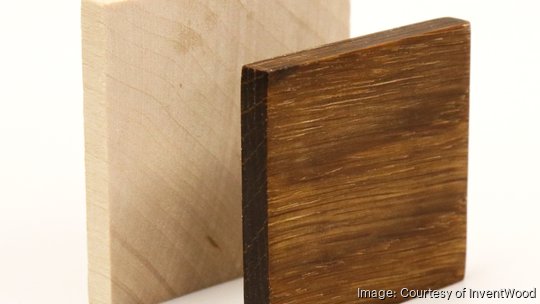

MettleWood is a lightweight material created by compressing wood to make it stronger and resistant to water and fire. The material is so strong that the company is considering using the product to create a low-cost alternative to Kevlar, as the company claims a few layers of MettleWood can stop a bullet. The main use the company is exploring in the commercial market is to use it to replace materials that take a lot of energy to produce, like steel or concrete, in construction.

The wood is relatively straightforward to create. The company uses heat and pressure to make cellulose — the main component of plant cells — denser. InventWood’s process is similar to how carbon molecules are smashed together in the Earth’s mantle to create diamonds. Outside of MettleWood, the company has several products that use processed wood to replace other materials. One composite can be used for natural insulation and another is a transparent wood product that can replace windows. The firm is also developing a wood-based replacement for rubber.

"There's a video of one of the researchers at UMD bouncing a piece of wood like a rubber ball," Cable said.

Cable wants to use Frederick facility to prove that MettleWood can be produced cost-effectively. Once the process is established, he hopes to eventually move to a larger facility to make 100 million square feet of the product.

"We want to figure out ways not only to make the material better but to make it faster and cheaper," Cable said.

InventWood is planning to embark on a Series A funding round later this year to supplement the federal money. Since its founding at UMD in 2016, the company has raised $7.25 million in private capital.

Many companies worldwide are trying to find new ways to use wood in construction to create a more sustainable industry that is less dependent on metal and plastics. Another Maryland firm, Cambium Carbon, uses damaged trees to create “Carbon Smart Wood,” a composite for furniture and outdoor desks.