A Manassas startup setting out to make sustainable chemicals is ready to ramp up production for its first product thanks to an initial wave of funding.

Capra Biosciences Inc. has raised $1.8 million in an oversubscribed pre-seed financing round, according to co-founders Elizabeth Onderko and Andrew Magyar. The capital positions the biotech to scale its technology — a new type of bioreactor — after launching just one month before the Covid-19 pandemic hit and then immediately putting its growth on hold through the rest of 2020.

Today, it said, it's back on track to making chemicals safer and more accessible to other corporate buyers for their own products. “The goal of our company is to be able to provide these chemicals at a comparable price point, because expecting consumers to pay more for sustainable products — that’s not going to drive widespread adoption,” Onderko, CEO of Capra, said in an interview.

This latest funding came from a group of investors including Prithvi Ventures and Savantus Ventures, both of New York; E14 Fund of Cambridge, Massachusetts; GS Futures of San Mateo, California; Asymmetry Ventures of San Francisco; SOSV Investments of Princeton, New Jersey; and Wes Osbourn, president of Houston’s Antimo LLC.

The first steps

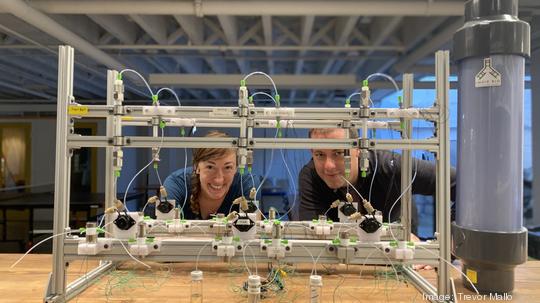

So what’s bioreactor technology, exactly? Think of a large stainless steel fermentation vessel at a craft brewery — great for making beer, for instance, but not as well-suited for products that come from petroleum, said Magyar, also Capra’s chief technology officer.

Capra’s modular reactor, however, is roughly the diameter of a fire hydrant and stands about 3 feet tall. The system grows microorganisms without requiring much water, unlike those giant steel tanks back at the brewery, which are also more expensive. Capra’s technology allows material to be added or removed continuously, and for multiple reactors to stack up easily — important, because the company can produce more chemicals with each bioreactor it adds. Onderko likens the concept to a data center, with a bunch of hard drives rather than one massive machine.

So the business, still pre-revenue, plans to put new funding toward building its first production-scale reactor. That will allow it to produce chemicals, then sell those chemicals to companies for their own products.

It starts with retinol, an ingredient made from petroleum and used in anti-aging cosmetics products. Up to this point, Capra has been cranking out samples, but it’s now looking to start selling its retinol product to cosmetics companies.

It is a top priority to begin generating revenue — and makes sense as a starting point, Magyar said. “If you jump into something that you need a lot of product to actually enter the market, it’s challenging to get your first product out there, and retinol is something you can sell in smaller quantities.”

The cosmetics space also has large consumer demand for sustainable and green products, Onderko said. “There are customers who are willing to seek out those products.”

The next steps

Capra intends to expand into lubricants, which it would sell to players in the aerospace market or chemical manufacturing firms like the Berkshire Hathaway-owned Lubrizol Corp. of Wickliffe, Ohio.

The ultimate goal is to help cut carbon emissions from chemical manufacturing by using biology rather than fossil fuels. But first, it’ll need to raise between $3 million and $5 million, which the company plans to do in about nine to 12 months, according to the co-founders. That funding would enable Capra to build a pilot facility of about 3,000 square feet to start, with space to add more production capacity as consumer demand goes up.

Until then, the partners are talking with potential customers, taking notes about the industry and getting the word out that it’s an option — all with an eye toward “leading the synthetic biology wave toward producing sustainable products,” Onderko said.

Capra Biosciences, based in the Prince William Science Accelerator, previously secured $500,000 through SOSV’s IndieBio program for early-stage biotech companies. Onderko developed the company’s technology as a postdoctoral associate at the U.S. Naval Research Laboratory with colleagues Sarah Glaven, Matthew Yates and Magyar, who at the time was a research scientist at Cambridge, Massachusetts-based Draper, which also has offices in Reston and D.C. Today, the team continues to have a cooperative research and development agreement with the Department of Defense.

“It just really captivated us, and the more that we talked about it, the more we were convinced that we could make a big impact on sustainable chemical production,” Onderko said, “so we decided to go for it.”