Integrity Orthopaedics Inc., a med-tech company that focuses on rotator cuffs, raised $20.6 million in a Series B funding round.

The round was co-led by Piper Sandler Merchant Banking and an undisclosed existing investor. The Minneapolis-based company will use the funds to expand the commercial launch of its initial product in the rotator-cuff-repair market. Integrity Orthapaedics was co-founded in 2020 by CEO Thomas Westling, Chief Intellectual Property Counsel and General Counsel David Crompton and orthopedic surgeons Dr. Patrick Connor, Dr. Howard Harris and Dr. Marc Labbe.

Westling and Crompton also co-founded Plymouth, Minnesota, med-tech firm Rotation Medical, which was acquired by orthopedics giant Smith & Nephew for $210 million in 2017. Rotation Medical made a device for treating rotator-cuff conditions by sparking new tendon tissue growth.

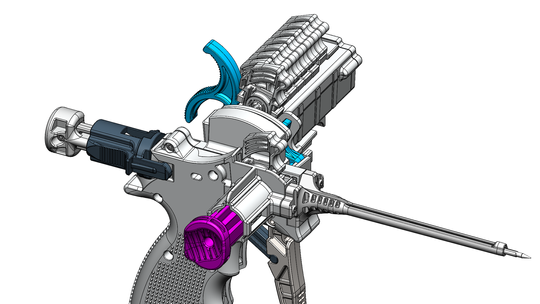

Integrity Orthopaedics' system is designed to reduce the occurrence of cuff re-tears following surgery.

The rotator cuff can have a lot of strain placed on it as the shoulder rotates in everyday movement. Rotator cuff repair patients are currently required to be in a sling to limit movement for six to eight weeks on average to allow for tendon healing, Westling said.

"Unfortunately, the data suggests that the rotator cuff fails to heal 20% to 40% of the time with these traditional methods," Westling said. "It’s currently one of the highest complication rates in orthopedics. Additionally, repair techniques haven’t evolved much over the past 17 years largely due to technological limitations of using a scope to make the repair."

In 2023, Integrity Orthopaedics received FDA clearance for its device, which is like an arthroscopic sewing machine.

"Our technique was inspired by a sturdy stitching pattern that's common in seatbelts and luggage straps," Westling said. "We thought if we could replicate this stitching pattern when attaching tendon to bone, there could be an opportunity for a much stronger and more stable repair while the body heals. Our mechanical testing has proven this superior strength and stability."

In his experience using the device, Connor said in a statement that it has shown that it creates a more consistent and efficient repair than other techniques and improves strength and overall healing environment during surgery.

"Based on the substantial increased strength of the repair and restoration of the entire rotator cuff footprint, surgeons may be more comfortable reducing postoperative sling immobilization for their patients, which will lead to their faster and more complete recovery," Connor said in a statement.

This year, the company is expanding its field sales team with the goal of working with orthopedists in select markets throughout the country. They expect the rollout of its system to increase over time as it ramps up staffing, production volumes and physician education resources.