A startup looking to transform grass into sustainable building materials is going into full production, a move that could mean hundreds of jobs.

Plantd, a Durham startup with SpaceX roots, announced this week that it’s launching production at its Oxford plant, with the first deliveries to homebuilder D.R. Horton (NYSE: DHI) scheduled for this fall.

It’s a fast rise for a material that has yet to be proven in the homebuilding sector. Co-founder Nathan Silvertail said that,as the company, which he says is currently at a $100 million valuation, continues to prove out its concept, the plan is to build another production facility out of state.

“We’re looking at around 300 hires for the next production facility, and I’m actually going to be in conversations with North Carolina about further expansion,” he said.

Right now, the company has 120 people at multiple sites, including the Oxford facility. The vision is to score more customer wins in the coming months as well as to close another round of funding.

From SpaceX to $100M company

It started at SpaceX. That’s where a pair of rocket engineers met and dreamed big — setting a vision that would become Plantd in Durham.

Silvertail was a senior build engineer. Huade Tan was senior life support systems engineer at Elon Musk's rocket company. As they built out their innovations within the company, developing environmental systems to be used by future spacecraft, they were racking up equity.

As SpaceX grew, the equity they were accruing gave them options.

“We got to a point where we decided we could stop working and enjoy life or enjoy a different challenge,” Silvertail said.

So they decided to jump all in on another passion, the environment, and work the problem. They started thinking about carbon sequestration — the capturing, removal and storage of CO2 from Earth’s atmosphere. Lots of scientists, entrepreneurs and academics were talking about it, but no one was actually solving the problem.

![Plantd Hemp OSB Prototype[1]](https://media.bizj.us/view/img/12124736/plantdhemposbprototype1*540xx1697-2262-225-0.jpg)

So, vowing not to be another talking head, they jumped in, soon connecting with Josh Dorfman, who would become the third co-founder, at an industry conference. Dorfman, who left Plantd earlier this year, had cofounded a furniture manufacturing startup in Asheville, Simbly, that used sustainable materials, but found it difficult to source premium plywood cheaply, particularly when looking for options with less environmental impact. It clicked with Tan’s line of thinking, and Plantd was born, opening its prototype lab in 2021.

Locating in North Carolina was an easy sell due to the state's combination of agriculture and industry. As Silvertail describes it, Plantd didn’t just need agriculture prowess. It needed a team with technical skills to create something not readily available. "We knew we needed to stand up our own supply chain,” he said.

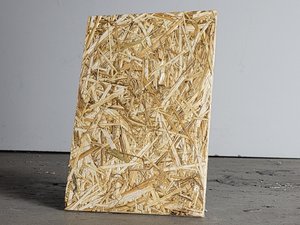

Initially, they experimented with hemp, but it proved expensive and difficult to work with.

Plantd needed to satisfy the needs of its customers but also check its own boxes — ensuring that whatever it was growing could be processed efficiently. The winner ended up being a type of perennial grass. The firm moved into an 80,000-square-foot production facility in Oxford to prove out the concept, crafting construction materials from the grass.

Growth plans for Plantd

Last year, D.R. Horton signed on as the firm’s first partner — a move Dorfman said at the time was “validating.”

“We’re in a fortunate position where it’s not build it and hopefully they will come,” Dorfman said last June. “In this respect, they’ve come, and they’ve said here’s an order. ... We know where those first products are going and we know there’s now a path to make sure they’re going into homes.”

D.R. Horton purchases structural panels for wall sheathing and roof decking to be installed in single-family homes.

Last year, the firm closed on nearly $13.9 million from investors such as American Family Ventures. Kyle Beatty, managing director at AFV, said at the time that he was impressed “by how they have reinvented every step of the production process from first principles, all the way from input material to logistics.”

Now it’s about execution, and scaling up. Negotiations are underway about a facility outside of North Carolina, Dorfman said.

The next phase of expansion will include finishing out the facility in Oxford, establishing more acres for material growth and building up that secondary operation out of state, complete with solar farms, he said.

The next phase is dependent on its ability to close a Series B round.