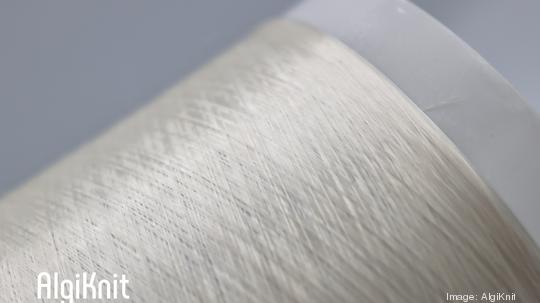

A New York-based startup that spins seaweed into yarn is setting up shop in the Triangle.

AlgiKnit plans to open an innovation hub in the Raleigh area next year as it tries to scale up production of its eco-conscious biomaterial. The space will house the company's manufacturing and R&D teams as it builds on its last four years of refining its technology.

"We've switched our focus from innovation to implementation," said company co-founder Aaron Nesser. "We've brought the technology on a small scale far enough that it's time to go bigger."

AlgiKnit was borne out of the frustration Nesser and the company's other two co-founders, Aleksandra Gosiewski and Tessa Callaghan, felt while working within the fashion and design industry. They had an interest in sustainability, but felt a lack of power with what they could accomplish given the materials available.

"We looked around and there wasn't anything we could use, anything that seemed accessible at the time," said Nesser, the company's chief technical officer. "So it was like, well, I guess we have to make it for ourselves."

They established the parameter of creating a sustainable textile and then identified potential materials that were abundant and renewable. They tried a variety of bio-derived materials before finding early success with seaweed.

"We found that we were able to work with this magnificent organism called kelp, and some of its byproducts, and transform that into something that was functional within the fashion and textile landscapes," company CEO Callaghan said.

Since identifying a material to work with, the company has pushed its technology to where it is now while producing its fiber at a lab scale. This work has been supported by the roughly $5 million the company has raised since its founding from investors like Horizons Ventures, SOSV and Fashion for Good.

This move to the Triangle, which it chose for the area's history in textiles and access to the research community, marks a new stage for the company. This will allow the company to increase the scale at which it can produce and open up opportunities to partner with brands. The company has some pilot projects lined up for next year that it can't yet share the details on.

With its move to the Triangle, the company also plans to double its staff of about 17 employees within the next year – local job postings are already up. This includes hiring on both the research and manufacturing sides of the business. Gosiewski, the company's co-founder and chief operating officer, will oversee the facility.

This step gets the company closer to its ultimate goal of becoming a commercial-scale material provider.

"If we're producing a product that is a net positive, beneficial material, literally the more we make, the more benefit there is," Nesser said.

The company is first targeting the fashion industry – which a January 2021 report from the World Economic Forum identified as the third largest polluter in the world behind food and construction – but sees other applications for its material.

"Just as cotton can be your favorite T-shirt and bed sheets, same thing with other fibers and ours," Callaghan said.

The company is approaching sustainability holistically and sees its product as one that can address numerous environmental issues associated with the fashion industry, such as fossil fuel usage.

"We've devoted our mission and now our business and our lives to maximizing the impact that we're able to create with this beautiful organism," Callaghan said.