A notable minority-owned Triad businesses is rapidly growing and making plans to add more space as it plunges more deeply into the pharmaceutical supply chain space.

With long-term contracts in hand with global companies for syringes and plunger rods and more under negotiation, the addition of a second medical-grade clean room in 2020 and a growing reputation among pharmaceutical companies, Greensboro-based Core Technology Molding Corp. is in the early stages of planning for more square footage at Gateway Research Park in east Greensboro.

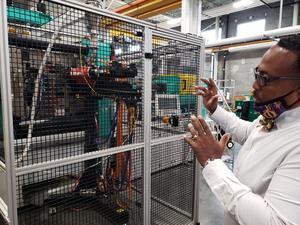

The maker of injection-molded plastics, including components for pharmaceutical, automotive and other industries, has been on a steady growth trajectory since 2015, and its demonstrated ability to respond to new market demand related to Covid-19 vaccines has provided an entrance into the global pharmaceutical supply chain market.

Core Technology has recently has benefitted from the need for pharmaceutical companies such as Merck (NYSE: MRK) and Pfizer (NYSE: PFE) to rapidly produce high volumes of syringe components. Once it demonstrated the ability to meet those supply chain needs, word spread quickly through the industry.

“We were already working with Merck, but now Covid just opened up more work for assemblies as well with Pfizer,” said Geoff Foster, founder, president and CEO of Core Technology. “That (Pfizer) was someone that we met a year-and-a-half ago, but we didn’t know if we would get any business with them.”

Foster, who was recognized as a 2020 Power Player by Triad Business Journal, said he can’t discuss volume or revenue details of the company’s contracts. He did tell TBJ that discussions are under way with other global companies, pharmaceutical and otherwise.

“In the pharmaceutical industry, they talk among themselves, and when they find out one has a good supplier, they share it,” Foster said. “Once one company does an audit, the others look at the audit report and validate us based on their competitors’ audit because they all have the same high expectations. When they see we passed a Merck audit with flying colors and we're certified, that puts them at ease that we we are the real deal.”

'Not everybody can do it'

In addition to Covid vaccines, Core Technology makes plungers for eight other vaccines including chicken pox, measles, mumps, rubella and shingles. Those are vaccines that have been around a long time, and will exist long into the future.

“Covid got us into the biological pharmaceutical space, which is hard to get into,” Foster said. “You have to have the right building, bring in the talent and you have to have certifications, and not everybody can do it.”

To meet the growing pharmaceutical production demand, Core Technology has already added a second clean room at its 35,000-square-foot facility at Gateway Research Park, a campus it shares with the Joint School of Nanoscience and Nanoengineering. The school is a joint venture between UNC-Greensboro and North Carolina A&T University, where Foster is an adjunct professor.

Those clean rooms, Foster told Triad Business Journal, were an investment of about $1 million, one that will pay off with the long-term contracts the company has in hand. Some of those include non-pharmaceutical customers — auto maker BMW, truck manufacturers Volvo Trucks and Mack Trucks, Husqvarna, Newell Rubbermaid and Parker Hannifin, among others.

In addition to pharmaceutical credentials, Core Technology has held a Tier 1 automotive certification for BMW since 2015, which allows it to supply the auto maker directly. It also holds ISO 14001 environmental certification, which is required to supply European auto and heavy truck makers.

“You have to have those two certifications, and they take time,” Foster said. “You just don’t get those overnight.”

A whole new building

The automotive, truck and other work doesn’t require clean room space, but it does require room that Foster said is in short supply in his existing building. He said Core Technology needs another 5,000 square feet in the short term, 35,000 more over the long haul. He is currently in discussion with Gateway Research Park management about building more space. The company moved into its current space in October 2018.

“I need a whole new building,” Foster said. We’re trying to figure out how to make it happen and Gateway has been a great partner. We have meetings here and they see the customers that are coming in and the contracts we're signing, and they're working hard to accommodate us. We believe we can build another building and connect with a catwalk or somehow where we can better utilize the same resources.”

More space, and more production, means more people. Core Technology currently employs 30. Foster says he needs to hire five more now, and by the end of the year he will need 15 more. Positions include engineers, project managers and production workers.

With his involvement with North Carolina A&T, Foster said he has the opportunity to “cherry pick” the best of the best from the classroom for engineering and leadership roles. The company also works with GTCC to train production workers who may already have experience in furniture, textiles, tobacco or other industries that have left the Triad, emphasizing opportunities for east Greensboro residents.

Although a small company, the long-term book of business and promising prospects allows Core Technology to compete with other employers for top talent.

“We're able to compete now on salaries and benefits where 15 years ago it was a lot tougher,” Foster aid. “Now we're able to compete on salary, benefits, 401k, all of that. With the types of resources and contracts with BMW and others, the long-term supplier agreements really help us secure the best engineering and production candidates in the area.”