Sometime soon, perhaps before the end of the year, the first ever cell-cultivated meat products will hit the U.S. market for sale. There’s a good chance a Bay Area company will be behind them.

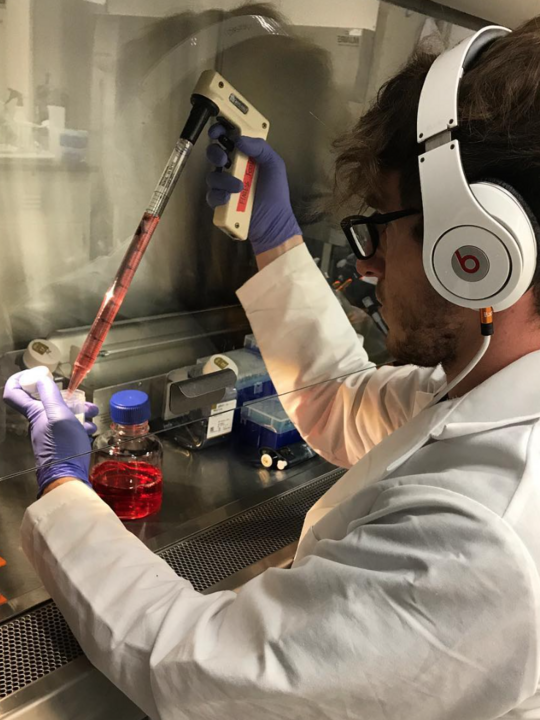

Scores of cell-protein startups have spent the last year and change exchanging notes with officials at the Food and Drug Administration and U.S. Department of Agriculture, the regulatory bodies that will ultimately issue the consumer safety and labeling requirements for cell-cultivated meat to hit the market.

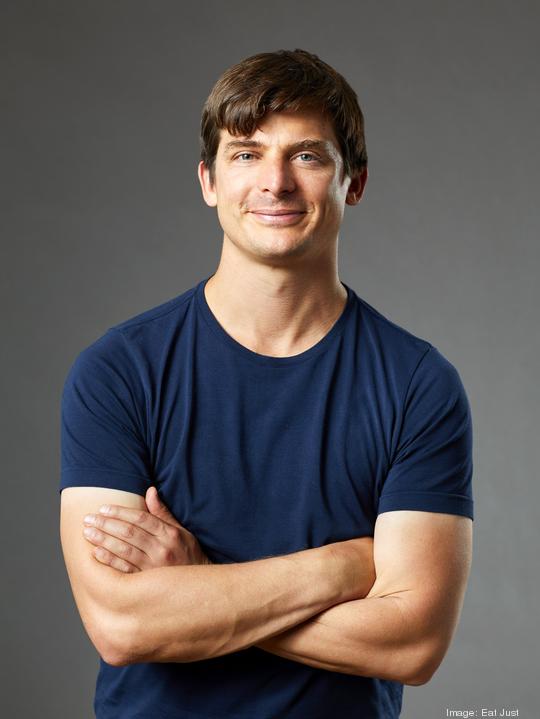

One local company, Eat Just Inc., is deep into discussions with the FDA and USDA regarding its cell-cultivated chicken. Eat Just achieved a historic first in December 2020, clearing a two-year regulatory process and receiving approval to start selling its cell-grown poultry via restaurants and even delivery in Singapore.

Eat Just’s regulatory feat perked the ears of competitors to ramp up their efforts domestically, and companies with the capital to invest are building relationships and production capacity in the big-ticket U.S. market, anticipating approval any day now. They’re also focused on China and Japan, where cell-grown seafood has already gained traction.

“There does seem to be a widespread belief throughout the meat industry that 2021 is the year that there’s some type of a breakthrough with a pathway to commercialization in the U.S.,” said Paul Shapiro, author of “Clean Meat: How Growing Meat Without Animals Will Revolutionize Dinner and the World,” and CEO and founder of The Better Meat Co.

Signs of the anticipation are everywhere: This summer, master chef Dominique Crenn announced she will feature cell-cultivated chicken from Berkeley startup Upside Foods on the menu at Atelier Crenn, the world-famous French restaurant in Cow Hollow that owns three Michelin stars.

“When I tasted Upside Chicken for the first time, I thought, this is it! This is the future of food,” Crenn said in a statement, likening the look, smell and sear to the real thing. “People are finally waking up to the downsides of conventional meat production, which led me to remove meat from my menus several years ago. Chefs need to lead the way in making more conscious product choices.”

Michael Selden, CEO of cell-cultured seafood outfit Finless Foods in Emeryville, told me the next company to pursue regulation in Singapore might only need a year or less. He’s hiring a team of new employees so the company can bring their efforts to bear in the U.S., Singapore and Japan.

“A lot of the rest of us are now doing the same thing and pursuing Singapore more aggressively than before,” he said. “We’re able to put more resources toward that project because it’s de-risked.”

Eat Just declined to comment on the nuts and bolts of its U.S. conversations, but did elaborate on its experience with the Singapore Food Agency. That process entailed submitting details on the purity, identity and stability of the chicken cells throughout the manufacturing process, descriptions of the production methods and then more than 20 full productions runs in 1,200-liter bioreactors to determine consistency.

The poultry was safety tested to meet standards for poultry meat, which found “extremely low and significantly cleaner microbiological content than conventional chicken,” Eat Just said. For good measure, the company said its product was also deemed safe and nutritious by an outside panel of international scientific authorities in Singapore and the U.S. representing expertise in medicine, toxicology, allergenicity, cell biology and food safety.

The stateside effort dates to March 2019, when the FDA and USDA announced a formal agreement to jointly regulate the industry. For poultry and other meat, the FDA oversees cell collection, the development of cell banks and scaled-up cell growth and maturation production processes, while the USDA oversees processing, the suitability of ingredients and labeling. For most seafood products, the FDA regulates the entire process.

The agencies aren’t creating new standards or pathways to regulate these products, but rather incorporating these new products into the pre-existing frameworks, Berkeley’s Upside Foods told me in a statement.

“From the beginning we believed this pre-existing framework was and is a sensible and effective regulatory regime, as it allows both agencies to play to their strengths and oversee the elements of cultivated meat production that lie within their respective areas of expertise,” the company said.

No one knows exactly when the regulatory shoe will drop. But indications are it’s getting close: Many companies, including Upside and Finless, are parallel-tracking production capabilities with their regulatory discussions. Wildtype debuted a facility in Dogpatch earlier this summer — scroll down to read more about that — and Upside is constructing a pilot plant in the East Bay it expects to be operational by year-end.

Eat Just is scaling up production in Singapore and building out infrastructure in the U.S. The company is setting some of its biggest manufacturing ambitions in Qatar, where the company has partnered with the state-backed Doha Venture Capital and the Qatar Free Zones Authority to build an over-$200-million large-scale plant which could take about two years to complete.

“It may sound obvious, but the most important thing that we need to do to scale this is to make more,” Tetrick told McKinsey & Co. in a recent interview. “We’ve got to move from 1,200-liters scale to hundreds-of-thousands-of-liters scale, not just produced in Singapore, but also in the U.S., in Europe, and in China.”

The factors influencing the U.S. regulatory approval timeline include the quality and completeness of product submissions and descriptions sent to the agencies. The workloads of reviewers and degree of inter-agency coordination for new food products also play a role, Upside said.

Vested interests aside, the companies I spoke with had nothing but praise for the regulatory officials they’re working with. Michael Selden, the Finless Foods co-founder and CEO, and Shannon Cosentino-Roush, Finless’ new chief strategy officer, said they were impressed by the transparency and communication they’ve had in the back-and-forth (and back-and-forth and back-and-forth again) with the FDA regarding their cell-grown sashimi.

Armed with a law degree from Vermont Law School and expertise in fishery policies from consultant and field work across Africa, Singapore and Japan, Cosentino-Roush said the regulatory process has involved lots of coalition building and informal discussions.

She works not only with the regulatory agency but with seafood industry interests like the National Fisheries Institute and with other cell-cultured companies across product categories via the Alliance for Meat, Poultry and Seafood Innovation, or AMPS for short, as well as with consumer safety groups.

“It’s not often the case that you’re building a regulatory pathway while an industry is coming to life and getting to market,” Cosentino-Roush said, describing it as a “come early and come often” dialogue and a “living process.”

“There’s nothing nailed to the tree — it’s a process the FDA is still figuring out,” she said.

The two main fronts where Cosentino-Roush interacts with the FDA are in pre-market safety and labeling. In October 2020 the FDA put out a request for information so industry stakeholders could inform the FDA’s labeling criteria for cell-cultured meat products. At its basic level the language has to distinguish the cell product from other methods like fish farming (or aquaculture) and also not disparage other industries. So the question of “can we just call it tuna?” gets a bit complicated.

“We ended up being able to align the majority of the answers around ‘cell-cultured’ and submitted a joint letter with AMPS and the National Fisheries Institute to the FDA in response to the RFI,” she said. “If we all kind of lean in, we can have something that’s common sensical enough and clear enough for consumers, even if it’s not everybody’s favorite.”

Selden described the FDA’s process evaluating food safety as “very modular.” He and his team are constantly swapping informal notes with the agency about the likelihood of this-or-that part of the process meeting approval standards. Each part is examined individually then ultimately in context as a whole, he said, adding this “iterative” approach makes it easier for the agency to keep pace with companies as their manufacturing processes are constantly tinkered.

“It’s just putting things into categories and buckets in a way that’s really helpful and how that will change regulatory timelines and guidelines. They’ve been very descriptive,” Selden said. “It’s a very easy conversation to have, and so without giving away 100% of our media formulation, we already have a good sense of what’s going to happen with it.”

The FDA is thinking about production workflow, procedures for replacing machinery, how much exposure the materials have to human interaction and open air throughout production (the less, the better). Selden admits the scrutiny is “strict” but ultimately that’s necessary — it would be more dangerous, and require hiring more people tasked with safety, without the FDA’s framework.

“I have a lot of confidence that they’re doing things in a way that works for everyone, something that’s thorough assessing the safety of what we’re doing but it’s also efficient and doesn’t keep us from market forever,” Selden said. “We’re building a pilot facility and they’ve given us tons of really helpful input in how to build this thing in the safest, most efficient and productive way possible.”

“It’s possible that you could see products on the market by the end of the year,” Selden said. “I personally would peg that as a little ambitious. But it’s certainly possible.”

BAY AREA CELL-CULTIVATED MEAT COMPANIES

Upside Foods (formerly Memphis Meats)

- Headquarters: Berkeley

- Products: Chicken, duck, beef (meatballs)

- Funding: $206 million

Artemys Foods

- Headquarters: San Francisco

- Products: Beef

- Funding: $26.5 million

Mission Barns

- Headquarters: Berkeley

- Products: Duck, pork and chicken fat

- Funding: $28.4 million

Eat Just

- Headquarters: San Francisco

- Products: Chicken, Wagyu beef under GOOD Meat brand

- Funding: $440 million (Eat Just), $267 million (GOOD Meat)

Finless Foods

- Headquarters: Berkeley

- Products: Seafood (tuna)

- Funding: $25 million

Wildtype

- Headquarters: San Francisco

- Products: Sushi-grade salmon

- Funding: $20 million

New Age Meats

- Headquarters: Berkeley

- Products: Pork sausage

- Funding: $32 million

INSIDE WILDTYPE'S DOGPATCH VENUE

Wildtype is thinking ahead.

Earlier this summer, the San Francisco alternative protein startup debuted what it says is the world's first fully operational facility for mass production of seafood cultivated from animal cells. The location: a 7,700-square-foot former microbrewery space in the Dogpatch neighborhood.

Founders Justin Kolbeck and Aryé Elfenbein said the pilot plant will allow them to produce 50,000 pounds of sushi-grade salmon fillets per year. It could turn out 200,000 pounds annually once the operation is fine-tuned, they said.

The founders said the feat is a step forward for the industry as its leading companies transition from a period defined by quests for proof of concept and attracting investment, to the next frontier, which (fish puns aside) is all about scale. Wildtype is preparing to be market-ready with its product by the end of the year, the founders said when reached for comment, should regulatory agencies approve a cellular meat product for consumption.

Once its product is approved, Wildtype intends to use chef partnerships to get its product onto the menu at sushi restaurants, the founders said.

Wildtype’s founders said hope the facility will also mark a milestone in transparency for their industry. A tasting room (dubbed “The Dock”) staffed with professional sushi chefs is expected to be completed by the end of the month, and will allow guests to sample Wildtype’s salmon and learn about how it’s made.

A floor plan of the facility, designed by architect Shuo Zhai of Gehry Partners LLP, includes bleacher seating for documentary viewings and space for tours through the facility for local science classes.