An Oakland startup is using artificial intelligence and robotics to tackle two big issues in the construction industry: waste and a labor shortage.

Urban Machine is developing a large, yet portable, robotic disassembly line that can automatically remove metal bits like staples, nails and screws from lumber that's collected from construction and demolition sites.

Each machine weighs 45,000 pounds, or a little over 22 tons, and reaches 80 feet long. Heavy duty vehicles like semi trucks, for comparison, can weigh up to 80,000 pounds, according to California regulations.

The company's goal is to be able to process at least 16,000 feet of lumber daily, on par with commercial virgin lumber processing.

The company has built three prototypes, and the next one will be able to be loaded onto a truck and transported to construction and demolition sites.

Urban Machine was founded in 2021 by CEO Eric Law, CTO Andrew Gillies and Alex Thiele. They won a pitch competition at South By Southwest in Texas earlier this month in the "smart cities, transportation and logistics" category.

Other wood reclamation companies are "pretty niche," Law told me. "They go after really high quality, super old growth material. So, think about your barn wood folks, for example. It's pretty low volume … Most people believe it's less than 1% of wood that gets reclaimed today."

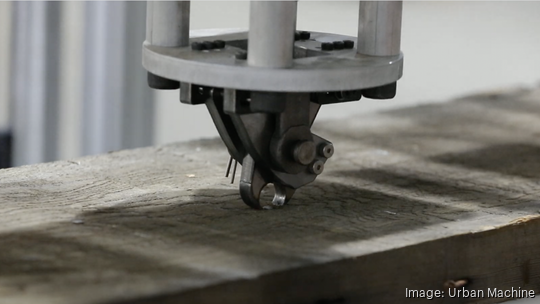

The company's machines use computer vision to identify which type of metal pieces need to be removed, then AI-powered algorithms help identify what type of fastener is present and finally a robotic arm with manipulators pulls or screws the metal out.

All of the wood processed is then sold to commercial manufacturing companies for reuse in prefabrication projects, which can handle the type of dense, hard wood that Urban Machine reclaims.

Urban Machine currently has around a dozen employees and primarily operates in the Bay Area, but it has plans to deploy a dozen of its machines across six cities in 2024.

Each machine requires five or six people to operate it, and the company estimates there's a need for 6,000 machines around the country in order to work towards reclaiming around half of all the lumber that would otherwise be wasted.

Eventually, Law envisions selling or leasing the machines with a software layer, as well as maintaining rental fleets.

The company has raised $7.2 million through a seed round. And its investors include GV, Lowercarbon Capital, Catapult Ventures, Klein Venture Partners and Union Labs Ventures, according to PitchBook.

Law has spent more than two decades working in the construction and technology sectors.

After studying mechanical engineering at California Polytechnic State University, he worked as a project engineer for Kiewit. By 2006, he founded EADOC, a software provider for the construction industry which was acquired in 2015 by Bentley Systems, where he stayed for a few years before hopping over to Swinerton.

While at Swinerton, Law oversaw the contractor's innovation division focused on experimental research and development to find solutions for challenges in the construction industry.

Initially, the effort involved working with startups to prove out early concepts that could address the industry's labor shortage in a variety of areas including automation, workflow, robotics and prefabrication. And then it evolved to include sustainability.

"We ran innovation challenges," Law said, and then "we were doing research on those waste streams from different divisions and looking at, where does concrete go? And steel and plastics and glass and wood. And that's really where I learned about the problem. The solution for it was completely outside. Swinerton was not about to go invest millions of dollars in a robotics company to reclaim lumber. So that's why I decided to leave Swinerton to go start this initiative. Because I got to combine my passions for construction and technology and sustainability."

The construction industry is facing a shortage of half a million workers despite job openings increasing 17% in 2022, according to the Financial Times, impacting 80% of all construction companies in the U.S.

And in 2018, construction and demolition debris from buildings, roads and bridges — including but not limited to wood — reached an estimated 600 million tons, more than double general municipal waste, according to the Environmental Protection Agency.

Globally, the market for reclaimed lumber is expected to grow 4.6% annually and exceed $70 billion by 2028, according to a report by Grand View Research.