Editor's note: In our 2023 Startups to Watch feature, the Silicon Valley Business Journal and San Francisco Business Times present startups and founders doing unique things in the Bay Area. Fizz is one of 15 we profiled this year — to read more about our mission and the other startups we're featuring, click here.

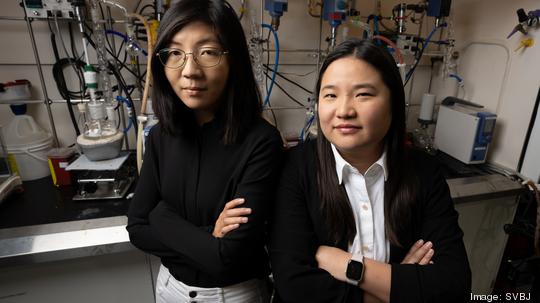

Best friends since high school, Miranda Wang and Jeanny Yao have been thinking about how to cut back on plastic waste for more than a decade. But it wasn’t until this year, when their company, Novoloop Inc., scored its $21.4 million Series A round, that they had enough funding to start really seeing their vision through.

Wang, Novoloop's CEO, is relieved that people have started to recognize what their company is trying to accomplish and happy to be working with her friend. “Most startups fail because their management team has a fallout,” she said. “We’re just very fortunate that the probability of that is extremely low. We spend our energy thinking about the challenges up ahead and how we can succeed at those.”

Describe what your business does? Miranda Wang: Our interest is looking at plastics that really no one else can recycle, and saying, “How do we turn this material into a circular material through chemistry?” Roughly only about 9% of all plastic produced actually gets recycled. So, we are addressing a really big piece of this plastic waste problem. We have created a technology process and a product, which is a highly elastic material that can be used to replace rubbers in lots of products.

- Founded: 2015

- Founders: Miranda Wang, CEO; Jeanny Yao, COO

- What it does: Take plastic waste and convert it into a new, high-performing material

- HQ: Menlo Park

- Employees: 35

- Total funding: $25 million

What was the “aha” moment behind your startup? We’ve been working together on developing plastic recycling innovation since we were in high school. We discovered the scale of this problem when we visited a waste transfer station in high school on a field trip. This is in Vancouver, where we grew up. We’ve taken a really long journey to get to this point, started a science tour competition, TED Talk, accelerator program, and so many steps. The big breakthrough “aha” point for this company specifically was around figuring out what do we do with polyethylene waste. What are the different ways we can chemically transform it? And what do we create from it so that we actually can have a viable business?

How different is the company you have today compared with the company you first envisioned? When we started out, the question was, could we use new synthetic biology tools to genetically evolve or modify microorganisms so that they learn how to eat and break apart the plastics? We studied that in university for a number of years, and we eventually learned that first, it's extremely slow for microbes to break apart plastics. Also, when microbes do break down plastic chemicals, they just turn it into CO2. And that's actually not good from a climate perspective. That was the point when we started realizing if we want to use plastic waste as a starting material, as a feedstock to manufacture some sustainable products, probably biology is not really the right way to go about it. Instead, we thought we should look into industrial chemistry and see about ways to chemically convert plastic, which would be a much faster reaction.

Who are your customers? Plastic converters, compounders, and consumer brands seeking climate-friendly, circular performance materials. Our most recent collaboration was with On, a Swiss athletic brand that makes running shoes, for a show called the Cloud Prime. It's still a prototype shoe, essentially a concept shoe so you can't buy it yet on the market but we are supplying shoe sole for that product and replacing rubber for that application.

How do you plan to scale? We want to build a production facility to scale-up our proprietary process technology and sell sustainable materials. This year, we're actually going through the design process. We've finally gotten to a point in our technology where it's mature enough for that, and also we have validation from customers that our product is the right product. So we're just figuring that out. We're looking at co-locating our technology, our plant with some existing facility.

What other businesses and business leaders give you inspiration? Elon Musk, SpaceX and Tesla. Elon Musk is looking at pushing the frontier of so many different hard tech spaces, and that's something I really look up to or feel inspired by. Another thing is the fact that he just keeps going. It's not like you go and you do a project, you make a ton of money and you're just done for life. There's so much to be done in this world, especially in the era that we live in, where our climate is under attack in all directions.