The Sacramento Inno Awards recognize some of the year's most talented and successful players in the tech and startup community. This year, the Business Journal recognized companies, products, and leaders in the innovation space. 3D-OPS is the company behind one of this year's Innovations of the Year.

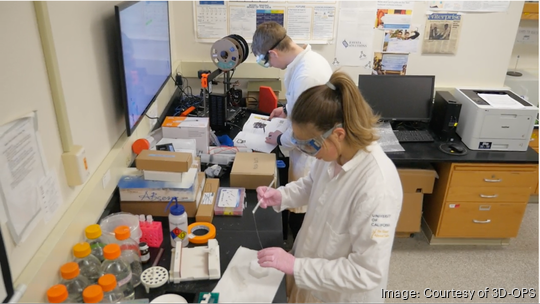

The company 3D-OPS began in the basement of the library at the University of California, Davis.

Haley Noelle, an undergraduate biology student, approached two of her friends, Avery Williamson and Preston Vanderpan — both engineering undergrads — about an idea that had been nagging at her for years.

“Do you think, theoretically, you could make a robotic spider out of a 3D printer?” she asked them.

Four years later, they’ve done it, and raised more than $50,000 in grant funding to study their inventions’ potential to help more people gain the feeling and use back after a nerve injury.

Noelle said that more than 20 million Americans are suffering from nerve damage, and 40% of interventions to repair them are not satisfactory.

“These patients will not regain full function or even optimal function of these areas again, motor function or sensory function,” she said.

That’s because, usually, the surgery to repair the nerves involves suturing them back together — which creates inflammation and scar tissue.

That’s where 3D-OPS comes in. They’re developing a medical adhesive that can essentially glue the nerves back together, without damaging them further, out of a synthetic version of the silk that spiders produce to spin their webs.

It turns out, spider silk is a pretty useful material. It’s stronger than steel by weight, more elastic than Spandex, and more adhesive than super glue. People have been trying to use it in medical applications for millennia — the ancient Greeks used spider webs to clot blood and dress wounds — but efforts to produce it commercially haven’t produced results so far. The spiders do not do well in captivity, and when scientists try to reproduce synthetic spider silk, it doesn’t have the same properties as the natural stuff. Until now.

“There’s been a lot of trying to force biology into pre-existing technology,” Noelle said. But the 3D-OPS team is taking the opposite tactic.

“We’re creating a technology that mimics biology,” she said.

Noelle and her cofounders started with a cheap filament printer, gutted it and rebuilt it, using the inside of a spider as a blueprint.

“If you’re not mimicking all of the processes that are happening in the spider naturally, you’re not going to end up with the same product,” she said.

Their material is being tested right now to make sure it is safe to use internally in humans.

Noelle said their printer can recreate spider silk with a number of different properties. Right now, they’re looking at this glue for nerve damage, but it also has potential in bone repair for delicate areas like the hand.

“It’s a really exciting material,” she said. “And a really exciting time.”