Most soft body armor used in the military today works great when it comes to stopping a bullet, but less so when it comes to absorption, still leaving most bullet victims with bruises, tissue damage or broken bones.

Now, a recent Bryant University graduate and MassChallenge Rhode Island participant is working to create a better solution.

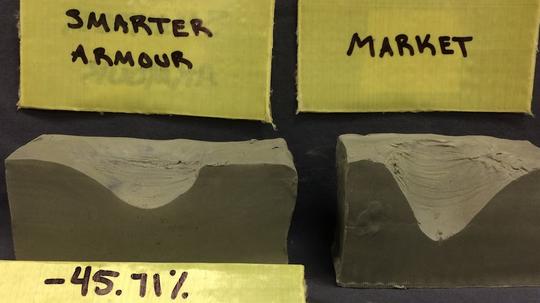

Richard Hollis has founded the company Smarter Armour, which is developing a material that can reduce the impact from bullets by 45 percent — and hopefully more in the future — so body armor vests not only block bullets, but also reduce injuries as well.

The patent-pending material combines ballistic aramid fibers such as Kevlar or Twaron with impact absorbing properties, and is about 8 ounces heavier than most current material used in body armor vests.

“If I go to market and it makes an impact on somebody’s life, it’s worth it."

“Vests right now are designed to focus on light weight and fitness to say, ‘We have the most comfortable vest,’” Hollis told Rhode Island Inno. “But in these suits, blount force trauma is being sacrificed. We are focusing strictly on the ballistic and impact portion of the suit.”

Hollis initially came up with his idea during a class project at Bryant University. He had been extremely interested in the impact absorbing materials sometimes found in protective equipment, such as lacrosse pads. However, he thought the technology could have other applications, which is how he stumbled across the military.

While the company could go to market right now, Hollis said his experience in MassChallenge has made him want to get the impact reduction much more than 45 percent.

“We have material that works and we could go to market, but we are not 100 percent and I wouldn’t feel confident not being 100 percent,” he said.

Although the focus is on body armor vests, Hollis said recent conversations he had with officials from the U.S. Department of Defense opened his eyes to other opportunities for Smarter Armour, avenues such as applying the material to armored vehicles and even explosive disposal units.

In the near term, Smarter Armour hopes to partner with another Rhode Island company, institute or university to improve the product. Hollis said he is currently planning to license the material out because it would be too difficult with his current resources to compete against the big manufacturers, although manufacturing might make sense someday.

The biggest short-term goal, he said, is working toward a phase 1 Small Business Innovation Research grant and perhaps also applying for some funds from the Rhode Island Commerce Corporation.

Long term, Hollis’ priority is getting Smarter Armour out into the world, where it can do some good.

“Whether or not I make $1 on this is not a deciding factor,” he said. “If I go to market and it makes an impact on somebody’s life, it’s worth it. It’s cool to be a part of something bigger than yourself.”