Cannabis has an obvious economic presence in Portland, home to some 227 retail stores, and it’s probably not difficult to imagine the growers, product makers and distributors that supply those shops.

But the weed economy runs deep and in perhaps surprising directions. Which gets us to Luna Technologies.

The Portland startup designs and builds machines that use a hydrocarbon, typically butane, to concentrate fresh-frozen cannabis.

The live resin products the machines yield deliver the full spectrum of what the plant has to offer, rich in the pungent terpenes that cultivators nurture, aficionados swoon over and that Dr. Ethan Russo — he of “entourage effect” fame — have identified as integral to the cannabis experience.

Luna didn’t invent what is known as BHO extraction, for butane hash oil. But it has applied sophisticated engineering know-how to automate a process that traditionally enlists “extraction artists” who manually operate machinery prone to inefficiencies, risks and miscues.

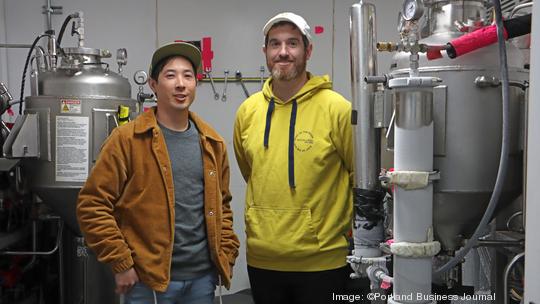

“We’re a company of engineers,” Jack Naito, Luna’s co-founder and president, said. “We come from aerospace and oil-and-gas and pharmaceuticals. Whereas before BHO extraction was about welders who started by building equipment, we’re engineers who started by designing equipment.”

Boeing out

Naito, 33, is a Portland native and, yep, a grandson of the late, great civic leader Bill Naito. After earning a master’s in mechanical engineering from the University of Washington, in 2015 he headed to St. Louis for a job as a materials processing and physics engineer with Boeing. He did R&D on automating composite materials fabrication. He found the work slow, bureaucratic, lacking in creativity.

That left him open to the entreaties of lifelong friend Kyler Buck.

Buck was in BHO extraction, dealing with machinery that featured repurposed brewery parts that required five people to operate.

“Jack being the smarted person I know and doing engineering at Boeing, I knew he could find a better way,” Buck said.

He lured Naito back to Portland in 2016 to work with him. Naito was astonished at what he found.

“There were extractors working on equipment that looked like it came out of a mad scientist laboratory,” he recalled. “There were stainless-steel vessels everywhere, hoses and valves just covering the room, people in lab coats who probably shouldn't have been in lab coats running around. It was chaos.”

Within months, Naito went from working with Buck to partnering with him, along with Buck’s Bobsled Extracts partner, Stephen Sweeney, to found Luna. Naito took a simple approach to scoping out a product: Solve Kyler’s problems, foremost of which was how to scale production and maintain consistently high quality.

IO Extractor

What it yielded, over time, was the IO Extractor. Operating it consists pretty much of loading in a sock filter filled with several 5-pound pucks of compressed, frozen cannabis biomass, and hitting a few buttons on a tablet touch screen or phone. The machine can be run virtually around the clock with minimal staffing.

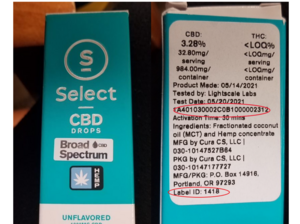

Luna software provides different recipes for a wide roster of dabbable end products such as sugar, shatter, terp sauce and diamonds. BHO extract can also be finished for use in vape carts.

The extractor was introduced in 2017 and it got Luna to profitability by 2019. Self-funded save for one short-term family loan, cash flow has fed careful growth that now has more than 50 Luna machines in operation. The company has 18 employees.

Naito declined to reveal revenue, but said Luna expects to see 45% growth in sales this year. The company added an ethanol extraction unit to its portfolio this year. The ethanol process doesn’t deliver the terpene profile of BHO extraction, but it can provide an economically attractive input for vapes, edibles and other products.

Luna is in many ways just like any other equipment manufacturer, but the sector it serves does bring unique challenges. Banking, for instance, is a frequent issue.

“We went through a period of losing three accounts in six months,” Naito said. “One day you wake up and you have seven days to move everything to a new account.”

Some suppliers have also been unwilling to work with the company because of its cannabis connection.

But market trends have been a wind at Luna’s back, with consumers seeking the high-end products its machinery can help deliver, and price pressures compelling companies to become more efficient.

Luna has made a mark in the industry, said Jason Showard, who chronicles the industry as producer and host of “The Modern Extractor” podcast.

“Luna’s automation systems are moving the industry forward, without a doubt,” Showard said. “For years, operators have been referred to as ‘extraction artists’ and have had to make process decisions based on limited inputs. Instead of an operator’s eye looking through a small sight glass to decide when to turn a valve, the system can now look at much less subjective, quantifiable inputs and make that decision based on the parameters set by an expert.”

CLOSER LOOK

Company: Luna Technologies

What it does: Designs and manufactures automated cannabis extraction equipment

Location: Northeast Portland

Founded: 2016

President: Jack Naito

Employees: 18