Despite a growing factory footprint, that will soon include Ohio and Germany, the technological heart of Intel will remain in Oregon.

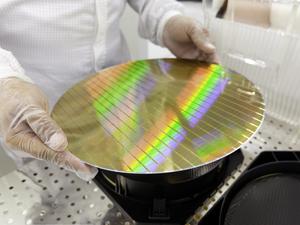

So said the company in a Monday event at which the company opened its latest expansion at its Hillsboro chip factory, or fab. The $3 billion-plus project added 270,000 square feet of additional cleanroom space to the site.

In addition to opening the latest Oregon expansion, Intel announced it is renaming the Ronler Acres site after company co-founder Gordon Moore. Gordon Moore Park at Ronler Acres honors the exec who coined Moore's Law, which states the number of transistors that could fit on a chip would double about every two years. It is the driving rule at Intel.

The chip manufacturer entered Oregon in the 1970s, with its manufacturing research and development hub — where its engineers devise every new generation of smaller, more powerful chips — located here. Those instructions are sent to Intel's factory network for exact replication.

That isn’t slated to change, said Sanjay Natarajan, senior vice president and co-general manager of Logic Technology Development.

“The plan is Oregon will always be the leading edge and the site where we do the next node (or generation of product),” he said.

The new factories planned for Ohio and Germany will join the factory network and receive the latest architecture and manufacturing instructions for volume production, Natarajan said.

Intel first announced it would further expand the facility, called D1X, at Ronler Acres in December 2018. The project adds 1.5 million square feet to the site’s existing roughly 4 million square feet. The entire Ronler Acres campus is 450 acres, roughly the size of downtown Portland.

This fab expansion — called Mod3 since it is the third expansion to the facility — will feature more than 1,000 chipmaking tools that each cost millions of dollars. That huge building cost explains why only a handful of companies manufacture leading edge chips. Many companies design chips but send the manufacturing to foundries for the actual production.

Intel has typically used its fab network to manufacture its own chips. However last year, new CEO Pat Gelsinger launched an aggressive manufacturing-focused strategy and launched a foundry business for Intel.

The company employs more than 22,000 people in Oregon, with about 14,000 of them on Ronler Acres. Natarajan said more investment in the site is planned following this expansion.

Though the expansion started before Gelsinger took over as CEO, it is a critical part of his plan to turn around Intel and regain technological leadership in the industry. Intel lost its crown as the company with the most advanced chips after several high profile manufacturing stumbles and product delays.

Natarajan noted that Gelsinger has added about $1.5 billion more of investment in people and equipment for research and development work to get Intel back on top.

He reiterated that Intel is on track for reaching parity with competitors by 2024 and taking a leadership position in 2025. The company’s Intel 7 chips (formerly known as the third iteration of its 10 nanometer) are in production and Intel 4 (formerly 7 nanometer) is ready for production in 2022's second half.

On a call with reporters, Natarajan made clear that Intel had learned from past mistakes and delays. It's tracking milestones and other leading indicators in development and contingency planning to ensure execution going forward. Its researchers and engineers work on several generations of product at a time, with the most basic research looking six years out.

The company also wants to be the first High-NA EUV tool user in 2025. EUV (it refers to extreme ultraviolet lithography) was Intel’s less-than-full embrace of this tooling that led to manufacturing delays of previous generations of product. High-NA EUV is the next generation of these tools.

This Mod3 expansion is designed to accommodate these EUV tools, which require more space and weight considerations.

“Semiconductors are fundamental to U.S. technology leadership, our economy, and supply chain resilience," said Ann Kelleher, executive vice president and general manager of Technology Development, in a written statement. "Intel is the only company in the world with the majority of its process and packaging R&D and high-volume leading-edge semiconductor manufacturing in the United States.”