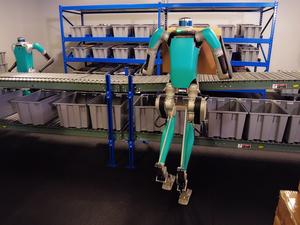

Oregon’s Agility Robotics reached a major milestone when Amazon unveiled a test with the company’s Digit robot within the retail giant’s R&D warehouse.

The Seattle company (Nasdaq: AMZN) has several Digit robots that now operate in a warehouse setting doing the repetitive task of moving plastic bins, called totes, from one place to another.

This is a big deal in the world of humanoid robots, where several companies including Boston Dynamics, Tesla and Apptronik are also in the mix.

“We are the only ones that are actually deployed with customers doing something useful,” said Agility co-founder and Chief Technology Officer Jonathan Hurst. “For 30 years, there have been demos and people building a robot that looks human and then talking about the excitement of it. But the path to get there is through the first purpose and the second, third, fourth, fifth and provide value to customers.”

Though the robots look slick in videos, Hurst noted these are still alpha products. The company now works closely with Amazon, and other yet-unnamed customers, to deeply understand the requirements and use cases those customers want. From there, the capabilities can be built for specific purposes and the robots can move toward more useful integrations.

General availability for the robots is slated for the end of 2024, when the company expects to ramp its manufacturing at its soon-to-be-completed factory in Salem.

The test with Amazon uses the robots in a specific location within the warehouse and for one purpose. Digit will pick up a tote from another warehouse robot, a conveyor belt or a shelf, then carry that tote and set it down where needed.

In announcing this test, Amazon took great care to say these robots aren’t replacing human workers but augmenting them. Hurst noted that this early work occurs within areas of the warehouse that are essentially islands of manual labor between heavily automated processes.

The humans who work in these spaces aren’t making decisions or thinking about tasks creatively. They are repetitively moving totes and are not allowed to wear headphones or listen to music due to safety regulations.

“Think of it that these robots are doing tasks, not jobs. Jobs and careers are different. The person put (on these tasks) is being treated like a robot,” he said.

He added that it's already hard to fill these repetitive roles. The logistics industry has 1 million unfilled positions, up from 600,000 in 2014, when Hurst first started working on robotics to bridge this gap.

“The whole vision of the company is to enable humans to be more human,” he said, which means removing repetitive tasks and allowing more autonomy and decision making in people’s lives.

At this point, Digit takes instructions through a tablet or touchscreen. So, humans can’t just talk to it. Digit could, well into the future take spoken instruction and perhaps move from a corporate tool to a consumer tool. The robot must first be able to meet the metrics, productivity, safety and information security requirements needed in a closed environment like a warehouse.

“We are ensuring we are not building a toy. We are ensuring we are building a tool right now,” Hurst said.

To move Digit beyond tests and into general availability, the company desperately needed more space. The new factory location in Salem came after much searching, Hurst said. The team wanted a facility near its engineering headquarters in Tangent, outside of Corvallis, but could not find anything that would accommodate hundreds of workers in that region.

The Salem location was already under construction and the building owner added aspects to the building to meet the company’s needs, Hurst said.

The company employs 250 workers and expects to add 100 more over the next year.

Last year the company raised $150 million from investors, including Amazon. That money was meant to get the first robots ready for general availability, Hurst said. The company will seek investment to scale in order to hit its production goal of 10,000 robots a year.