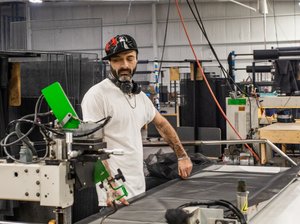

A new and automated production line is now up and running to make products from Murrysville-based FlexScreen, the creators of patented, flexible window screen inserts capable of being shaped into or out of many types of window frames.

Taking up 1,300 square feet of space, FlexScreen said its automated window screen product line is the first and only one of its kind, which is now operational at the company's flagship manufacturing facility in nearby Export, which spans 40,000 square feet.

"It was so exciting to finally see the FlexScreen automated window screen line being loaded off the truck into our facility," Joe Altieri, president and founder of FlexScreen, said in a prepared statement. "This technology has never been available until now, and it's going to change how window screens are made."

The automated line requires four employees to run and can produce one of FlexScreen's flexible window screens in under two minutes. FlexScreen envisions the number of operators required to run the automated line to decrease as it continues to make advancements to it.

But the company, which grew in notoriety after being featured in a season 11 episode of ABC’s “Shark Tank" in January 2020, isn't planning to use the automated production line just for the manufacturing of its own window screens. FlexScreen plans to license out the use of its automated line to other window manufacturing companies, several of which have already signed on to use the platform, FlexScreen said.

FlexScreen employs about 170 workers total, between 50 to 60 of whom work in manufacturing roles at its Export facility or in the company’s nearby corporate offices in Murrysville. It also maintains six other manufacturing facilities across North America.

In December 2022, Altieri told the Pittsburgh Business Times that FlexScreen had invested about $2 million over the prior year into its Export site to update the manufacturing process and renovate the interior to make it a better, more productive environment for workers.

“We’re a reinvestment company; that’s just what we are,” Altieri said last December. “We’re reinvesting into our growth, and we want to be 10 times larger than we are in the next couple of years.”

FlexScreen's products are found in big-box stores like Home Depot throughout the country.