Bear Machinery has made everything from precision components for some of the world’s largest telescopes to unmanned submarines to prototypes for surgical instruments, but it was a team project to build ventilators as a backup to Hawaii’s inventory that helped the 45-year-old company weather the Covid-19 pandemic.

The company got its name from founder Blair Stultz’s nickname and his bearded appearance in his younger days. Bear Machinery is very much a family business — his wife, Brenda Stultz, is the company’s president, son Mark has worked on the production side for 14 years and most employees have been with the company for more than a decade.

Blair Stultz founded the company in 1976 to do precision machining and custom fabrication with the astronomy and oceanographic sectors. The company was strategically located in Kaneohe to be close to the Naval Ocean Systems Center when it was at Marine Corps Base Hawaii. The couple owns its 10,000-square-foot building on a 13,652-square-foot lot leased from Kamehameha Schools.

Bear Machinery has worked on such projects as recreating a steel tube frame for an unmanned deep-sea submarine to making custom prototypes for bone plates and surgical instruments, with about 50% of its work today for the federal government or the military.

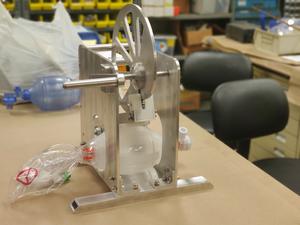

When the Covid-19 pandemic hit last year, business at first slowed down, but then Olin Lagon, founder and chief technology officer of Shifted Energy, called to ask if they would join Kahanu, a team formed to design and manufacture bridge ventilators. Bear Machinery made all of the mechanical parts for the project, funded by Hawaii Community Foundation.

Bear Machinery was able to keep seven full-time and two part-time employees working through the pandemic despite delays, thanks in part to the ventilator project and to the Paycheck Protection Program loan it received through First Hawaiian Bank.

How many ventilators did you make?

We made components for 200. We put 10 together for testing. And then the FDA changed regulations for an emergency use authorization. We just decided about a month or so ago to find some storage for the parts. Now, we’ll wait and see in 10 months and decide what we will do with all these components.

How has business changed for you since you started?

The company’s evolved so that we can do a higher level of work. We have more technology. You’ve got to have good service, and you’ve got to have high quality, because whatever you do over here [in Hawaii] is going to be more expensive than on the Mainland.

What’s the most unusual thing you’ve ever made?

We have a couple components on the James Webb Space Telescope, and we have one component on [NASA’s] New Horizons [telescope]. We’ve done work for Boeing, which runs the telescope over on Maui. They had to pull the primary mirror out of the telescope, and they didn’t have the lifting equipment, so we built a lot of the fixtures to pull it out. We had a crane out in the yard to pick up the 50,000- or 60,000-pound loads to test it.

Was that the biggest thing you ever built?

AES has the offloading for coal. And there was a surge hopper and a conveyor system that we built back in the mid ’90s. That was about 85 tons worth of steel. It was the largest physical thing that we built — so big, we had to build it out in the parking lot.

What is your biggest challenge?

Finding talented employees, those people with the right skill set. Right now, what is in high demand for us is a CNC machinist — CNC means Computer Numerical Control — somebody that can run a computer-controlled machine tool. And not just run it, but program it, set it up and then make parts. That’s a difficult skill to find in Hawaii. So we’re always looking for talent.

Bear Machinery

Brenda Stultz, president

Blair Stultz, vice president

Address: 46-153 Malina Place, Kaneohe, HI 96744

Phone: 808-247-6706

Website: bearmachineryinc.com