Northrop Grumman Corp. (NYSE: NOC), a global aerospace and defense company with a significant Central Florida presence, is leading a team that hopes to win a Navy contract to engineer and manufacture a new warplane.

Should Northrop win the award — which would be one of the programs funded by the Navy's baseline budget included in the 2024 fiscal-year defense plan, according to Henry Cyr, director of multi-domain command and control-capture programs — Northrop will leverage local suppliers, contract with small businesses in Central Florida and bring in other contractors from out of state to support the program.

The aircraft — which is referred to as E-XX and is part of the TACAMO program (Take Charge and Move Out) — will enable the President and other military leaders to communicate with nuclear forces during a crisis. A fleet of the new planes that serve as military command centers will replace a fleet of aging E-6B Mercury aircraft.

The proposal is due Jan. 22, 2024.

Why government contracts matter

The Department of Defense has contracted with businesses throughout the region for programs related to national security and war. At times, when larger companies like Northrop Grumman win awards for this kind of work, they subcontract or even buy technology from smaller tech companies in Central Florida.

Northrop’s team includes Lockheed Martin’s Skunk Works, Raytheon Intelligence and Space, Crescent Systems Inc. and Long Wave Inc. In developing the proposal, the group has been informed by the outcomes of simulation technology and a “digital-first” approach, which has been adopted companywide at Northrop.

A comprehensive digital transformation at the company means that these days, every new program undertaken at Northrop starts in the digital realm. Here’s how that came about.

Back in 2017, three Northrop Grumman engineers based in Melbourne approached their managers and asked for $200,000 for a special project.

Doug Young, Northrop Grumman vice president and Strike Program manager, said the engineers believed they could come up with a way to place digital models of airplanes in "a virtual environment to understand some of the production challenges of building the airplane.”

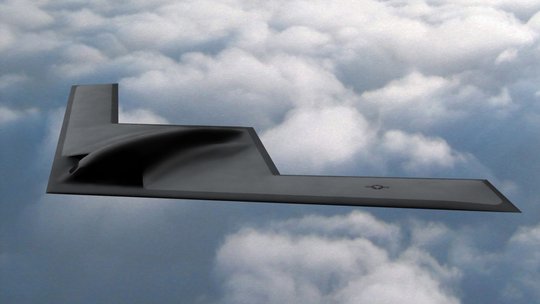

Then two years into an Air Force contract to develop and produce the B-21 Raider, Northrop leadership decided model-based systems engineering was the way to go if the company wanted to get the B-21 off the ground faster while reducing risk and cost associated with the program.

What began as a bright idea became modus operandi at Northrop.

Northrop showed Orlando Business Journal some of the rooms where the most modern technology is harnessed. One was an Advance Avionics Lab, where training simulators are developed. Training is one of the most popular uses of simulation technology and Central Florida is considered the global hub for this kind of tech. Advanced Avionics Program Manager Zak Upshaw said because of the DoD's ongoing digital transformation, often the contracts specify that programs "start digital" — built on a digital foundation that includes simulation technology.

Perhaps the room most relevant to engineering and production is the HIVE (Highly Immersive Virtual Environment). Infrared sensors around the room allow for full-body motion capture, creating a lifelike experience in, say, an aircraft. This is where simulations help catch design flaws early on, establish what a technician’s experience will be in real life, determine how parts will be removed and replaced, and more.

"Now, we're able to create a program from the ground up in a digital fashion using a lot of things we've learned on B-21,” said Cyr.

This is a notable fact given that the very program that built the Melbourne campus was awarded to Northrop in 1985, well before simulation technology reached today’s sophisticated levels. The company’s culture in Brevard County was built on the E-8 Joint Surveillance Target Attack Radar System, affectionately referred to as Joint STARS. Back in ‘85, the cycle of designing, building, prototyping and testing was risky and clunky by modern standards.

As of Nov. 6, Joint STARS is no more. The program is permanently concluded. But the leaders and teams that worked on Joint STARS aren’t stuck in the past.

After decades of military service, Cyr came to Melbourne specifically for Joint STARS and now runs point on the company’s efforts to win the new warplane contract.

“As [Joint STARS] started to divest, I was able to — not only me, but also other people from that program — take those skills, those digital engineering skills, and migrate them over to this Navy opportunity.”

He said the campus has grown exponentially since its earliest days. At first, Northrup had about 250 employees there. Now it’s about 5,000. Employees and staff all work on multiple programs, and the sundowning of Joint STARS won’t trigger any job losses as employees were routed to other projects, although some employees took voluntary retirement.

For more stories like this one, sign up here for Orlando Inno newsletters from the Orlando Business Journal and the American Inno network. And be sure to follow us on LinkedIn, Facebook and X (formerly known as Twitter).