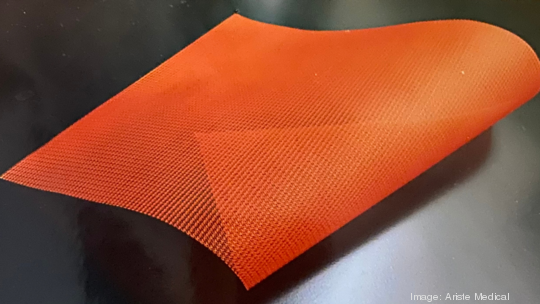

Medical device company Ariste Medical’s antibiotic mesh product has received U.S. Food and Drug Administration (FDA) 510(k) clearance.

Ariste Medical's polypropylene mesh product comes with an antibiotic coating of minocycline and rifampin, which reduces the risk of implant contamination during ventral hernia repair.

With 400,000 ventral hernia procedures performed annually according to the National Institutes of Health (NIH), infection post-surgery continues to be a concern.

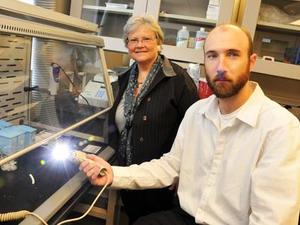

“There's a risk of anywhere from 8% to 40% [that] patients having open hernia repair may have an infection,” Ariste Medical co-founder Lisa Jennings, Ph.D., said.

When mesh products are compromised by bacteria growth or mesh infections, she said it becomes challenging not only for the patient but also for the surgeons, who may sometimes have to repeat the surgery to remove the contaminated product.

Ariste Medical's product helps preserve that mesh and its function, improving patient outcomes and reducing cost of care.

“We have a product with antibiotic coating that's going to inhibit bacterial contamination of that mesh,” Jennings said. “We're hoping that this will make a difference not only for the patient but also [for] the peace of mind of the surgeons as well.”

According to a Global Market Insights report, the hernia repair devices market crossed the $4 billion mark in 2021 and is expected to witness over 6.2% compound annual growth rate from 2022 to 2028. Increasing hernia cases and the growing demand for hernia mesh devices seem to be the factors driving this market growth.

The FDA clearance marks a significant milestone for the Ariste Medical team. It’s been a long journey for Jennings and her colleagues, going back almost 15 years.

Behind the scenes

The initial research and discovery of the technology happened at the University of Tennessee Health Science Center, Jennings said, through a collaboration with fellow co-founder and UTHSC colleague, Dr. Timothy Fabian. In 2007, they began work on a prototype drug-coated vascular bypass graft to mitigate graft failure caused by infection and scar tissue formation.

“The whole goal around the technology was to preserve the integrity of the surgical implant,” Jennings said. “We worked on an initial technology and disclosed that to the University of Tennessee Research Foundation as an invention and decided that we would like to have the opportunity to develop a surgical product.”

That’s how Artiste Medical began. Jennings, along with Fabian and Brian Best, another colleague with a career in commercial operations, founded the company in 2007 and licensed the technology from UTHSC.

The first five years at the company were minimal activity, Jennings said. It was the period of the Great Recession, and investment opportunities weren’t particularly robust at the time. Finally, in 2012, things got moving for Ariste when they received their first patent.

The patent was for the concept of their technology of coating drugs onto implants, like grafts. Soon after, they secured a small lab at the now-closed business incubator space at the Memphis Bioworks Foundation and even received an angel investment of $1.2 million. That funding helped support their efforts to open a research lab and further develop their technology.

From 2012 to 2015, the Ariste Medical team focused its efforts on research and development. Jennings said they concentrated on developing their proprietary coating and securing their technology and capabilities.

In 2015, an anonymous investment of $4.6 million to Ariste Medical boosted their operations. It helped them refine their coating, develop an automated device coating technology that allowed them to generate consistent products, and hire more employees.

"We were able to move forward on a variety of fronts to get to a point that we were approaching the development of a product that then could undergo testing to prepare us for filing to the FDA," said Jennings.

After nearly seeking FDA approval in late 2018, the team realized they needed longer-term studies. They put in the additional work, and the team finally submitted their FDA application in December 2021; And, in March 2022, they received the much-awaited clearance.

The FDA stamp of approval to market their product now opens a new chapter for presently pre-commercial Ariste Medical.

"It's very exciting for me to know we now have approval to market a product that can make a difference in reducing these [open hernia repair-related] complications," Jennings said.

Today, Ariste Medical has 16 patents across the U.S., China, and the United Kingdom. The company moved its commercial and production operations to Utah in 2020. Still, its research team, comprising Jennings and their production engineer, Olaf Schulz, continues to be based out of Memphis.

Over the years, they’ve also collected data for more diversified use of their technology across other materials and using different antibiotics.

While the company is still contemplating its next steps, getting to this point has been an exciting and gratifying experience for them, Jennings said.

“It's very rewarding to go from an idea that was generated as a university professor to now realize that we've achieved FDA clearance for that product,” she said.