Already one of the five largest genetic-material manufacturers of its type, Forge Biologics Inc. has landed an $80 million credit facility to speed buildout of its Grove City facility – where it now plans to grow to a total of 400 high-paying jobs.

MidCap Financial is backing the financing, which Forge will use to grow to a total of 20 biotech manufacturing suites through 2022, and add the industry's largest equipment a year to 18 months faster than planned because of growing demand.

That way it can effectively grow with clients that have been researching therapies and taking them through clinical trials: Forge will be able to make batches of engineered genetic material large enough for the larger late-stage trials and commercial launch.

Debt financing without giving up equity means the lender is confident Forge has enough revenue and upcoming demand to repay with interest. The company does not disclose sales figures.

"Doing a non-dilutive round is always a great signal," co-founder and CEO Timothy Miller said.

Forge had previously raised $160 million in venture capital, including a $120 million Series B last spring, with Columbus' Drive Capital LLC among earliest investors. By August it had reached 115 employees and started the next phase of interior construction at its a 175,000-square-foot warehouse. This year's buildout also includes a small exterior addition for a total of 200,000 square feet.

The company is developing gene therapies for rare and often fatal conditions, while also serving as a contract manufacturer for other researchers and pharmaceutical companies in the field.

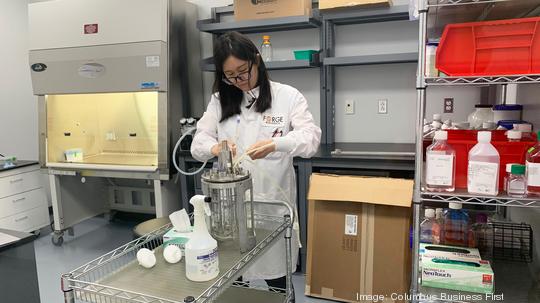

Gene therapy uses modified viruses – called vectors – to deliver copies of missing or defective genes to the body's cells. They're grown in vats called bioreactors, typically ranging from 1 liter to 500 liters in volume, which must be in super-clean rooms to prevent contamination.

The new financing will allow installation later this year of 5,000-liter bioreactors. Manufacturers just started releasing those models last year, according to several news releases.

Miller said he does not know of another facility using the equipment that, like Forge, specializes in the type of virus known as AAV, which is used in about 70% of therapies being researched. Not many have ceilings high enough for the 16-foot-tall vessels.

Forge has grown to about 140 employees, and is speeding up hiring along with capacity. Economic development group JobOhio has agreed to a job-training grant, which reimburses for certain expenses, with the amount to be released when the deal is signed, a spokesman said.

The company isn't hiring only Ph.D.s; it's also adding high school graduates and workers from other Central Ohio manufacturers, Miller said. It helps if that includes experience working in a clean-room environment, he said, but "we'll train it into people."

"The world-class researchers, talent and investors in Ohio have created an environment where Forge can develop life-changing gene therapy advancements that can positively impact lives worldwide." JobsOhio CEO J.P. Nauseef said in a news release.

Forge was able to start production quickly by buying an existing industrial facility and building clean-room enclosures inside it, rather than waiting 3 years while building from greenfield. Meanwhile, biopharmaceutical researchers face wait lists up to two years long to produce the material needed for studies and patients.

Columbus-based BHDP Architecture designed the Forge facility, and the Cincinnati office of Skanska, a Swedish firm with specialties including pharmaceutical industry construction, is the lead contractor.

Miller has spent 25 years in Ohio's biotech industry, including with a Cleveland trade group and seven years as CEO of a Nationwide Children's Hospital gene therapy spinoff. Becoming a major employer is "a big deal," he said.

"It's great to be a part of the group of hungry, ambitious entrepreneurs trying to bring up the biotech ecosystem," Miller said.