Don Sweeney, chief financial officer for Locus Fermentation Solutions, thinks his company's growth is about to take off.

The Solon, Ohio, biotechnology company recently raised $117 million in debt based on the value of its intellectual property — more than 1,300 patent filings.

And the company's chairman, CEO and co-founder, Andy Lefkowitz, has hit the trail to raise another $150 million in equity financing, company executives said.

Locus Fermentation is using its growth capital to add 100,000 square feet of biomanufacturing space in two Solon locations and double its Northeast Ohio workforce to grow, process, market and distribute more of its biological products, said Teresa DeJohn, the company's marketing and public relations director.

A year ago, one of the company's six operating companies, Locus Performance Ingredients, struck an exclusive agreement with Dow for the sale and distribution of its line of biosurfactants in the global home care and personal markets.

The operating companies, which serve agriculture, consumer goods, industrial, oil and gas, and mining markets, are looking at a handful of similar global growth opportunities this year.

"Every year we've grown, and they've been really nice growth paths," Sweeney said. "But if one, two or three of these opportunities were to hit this year, it would be a seismic shift in our growth."

Green solutions for industry

CEO Lefkowitz, an attorney, started Locus Fermentation in 2013 based on prior experience using microbial organisms in human and companion animal products.

In 1997, Lefkowitz and Sean Farmer, a West Coast microbiologist and fermentation scientist, started Ganeden Biotech, the Mayfield Heights, Ohio, company that developed a hardy, shelf-stable probiotic strain used in nutritional supplements, and added to food and beverages. Ireland’s Kerry Group acquired Ganeden in 2017.

Locus Fermentation

Growing consumer demand for "green" products, recent regulatory actions requiring companies to warn consumers about toxic chemicals in their products, and the Biden administration's $2 billion push to build the nation's biomanufacturing capabilities make now a good time to launch Locus, DeJohn said.

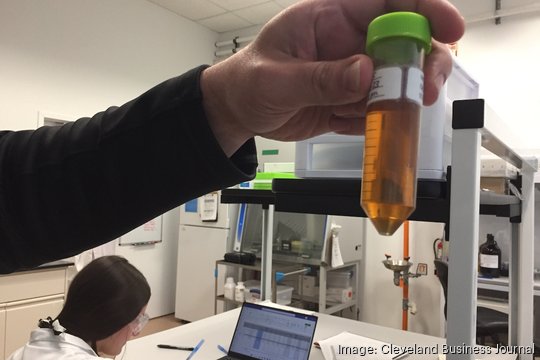

Locus ferments bacteria, yeast and fungi to produce biological materials that can take the place of chemical and synthetic ingredients in everything from soil additives for farmers to hydraulic fracturing fluids for oil and gas drillers.

Using microbes in industrial processes isn't new. But Locus has identified better microbes and figured out how to commercialize them cost-effectively and at scale, Sweeney said.

As a result, Locus Fermentation's products often outperform chemicals — and they're good for the environment.

A few examples

Locus Agricultural Solutions makes its own line of soil probiotics, marketed under the Rhizolizer brand, that enable dozens of crop categories to absorb more nutrients from the soil. Rhizolizer not only helps plants produce bigger crops, but it reduces the use of petroleum-based fertilizers, which, in turn, reduces greenhouse gas emissions.

Rhizolizer also builds plant root systems that sequester more carbon in the soil, creating a revenue stream for enabling farmers to sell carbon offset credits.

Meanwhile, Dow distributes some of Locus's biosurfactants — substances designed to reduce the surface tension of liquids in which they are dissolved — to cosmetics companies that use them to make their makeup spread smoothly.

These biosurfactants are produced by fermenting yeast and have the potential to be used in a wide range of applications, including wound healing, cancer and antimicrobial agents, food preservatives and food waste management, according to the National Institutes of Health.

Growing demand for using biosurfactants in soap, detergent, personal care and industrial cleaning products is expected to boost the market size to $14.3 billion by 2032, according to Global Market Insights.

Growing in Solon

Locus Fermentation and its operating units have been preparing to expand their production capacity in Solon for about a year.

The company recently leased an additional 70,000 square feet of production space for its biosurfactants business and an additional 35,000 square feet for its agricultural product production on Aurora and Cochran roads.

Locus already is producing biosurfactants in 850-gallon commercial fermenters — many times the size of the modest fermenting equipment the company started out using — at its Aurora Road location, said Scott Weber, vice president of production.

"What’s unique about our new facility is that most fermentation facilities can take years to set up, (but) we’re able to have a fermentation facility up and running in anywhere from six to nine months," DeJohn said.

The company already has doubled its production staff and facilities team and is in the process of hiring more project and fermentation engineers, as well as leaders, she said. Locus employs about 160 people, half of them in Northeast Ohio.

"We are at a point now where we've hired all the right people, we've bought all the right equipment, we have all our formulas, we have our distribution partners. We sort of have everything we need," Sweeney said.