Path Robotics Inc. has raised $56 million to perfect the engineering of its AI-driven autonomous welding robot and aggressively expand sales to manufacturers across the country.

New York City VC firm Addition led the Series B round, joined by returning investors Drive Capital LLC in Columbus, Basis Set Ventures of Silicon Valley and San Francisco-based Lemnos Lab. Path Robotics has raised a cumulative $71 million to date.

This year's revenue could be four to five times that of 2020, when the Columbus company grew rapidly through the second half of the year – mid-pandemic, cofounder and CEO Andy Lonsberry said.

"We're seeing that there's a lot of a lot of need out there," Lonsberry told Columbus Business First, a sister publication to the Cleveland Business Journal. "So we're going to be pushing our growth very, very quickly and utilizing that capital to sustain it and move as fast as we can to deploy to our customers."

Path has grown to 100 employees, up from 20 at the start of 2020, and could add more than 60 jobs this year. Most are remote, with a few in the headquarters inside a revamped warehouse at the edge of Scioto Audubon Metro Park in German Village.

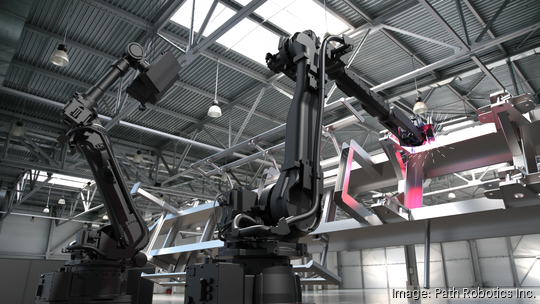

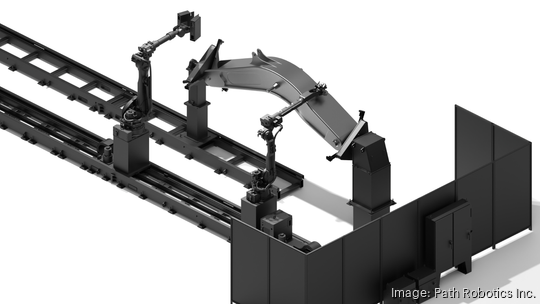

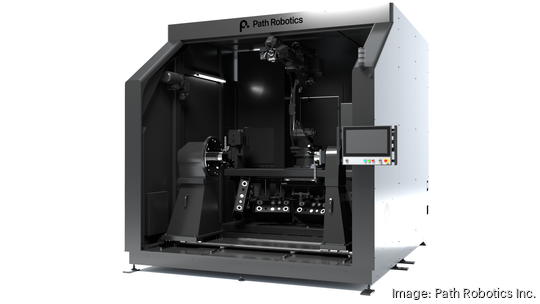

Path launched its redesigned production robot in July after developing and refining it for the past three years on the factory floor of its first customer, a Cleveland auto parts maker.

Most of what the company builds is machine learning software and a control system system of sensors and AI that it adds to mainly off-the-shelf robotics hardware.

"We're really trying to add that layer of intelligence to robots that allows them to learn from failure, that allows them to see what they're looking at, and to try to give robots the ability to add context to the operation that they're doing," Lonsberry said.

Instead of welding the same part in the exact same point in space again and again on an assembly line, the Path robot can load and unload parts and adjust if, say, there's a slight warp in the metal.

“Path Robotics is solving a complex and critical problem in our country by bridging the gap between the supply of skilled welders and demand,” Addition founder Lee Fixel said in a news release.

Addition is a VC firm with the patience to build a generational, long-term, unique company that can truly change an industry, Lonsberry said. The investors also bring deep expertise and a wide range of contacts in manufacturing.

"They really see the vision for the company," he said. "And what I've learned is that it takes a lot of capital to make that happen. And we want to be able to focus on supplying and building a great product and not having to focus every single day on just shipping, shipping, shipping."

Lonsberry and his brother, Alex Lonsberry, founded the company in 2014 as an engineering consulting firm in suburban Cleveland. Customer TMG Performance said its worst problem was not being able to hire enough welders.

Adding their father as a cofounder, the brothers set up Path in TMG's basement and worked on the AI augmentation to the human workforce. With the robot doing perfect welds on the drudge work for a given project, the human welders are freed up for more creative work (including programming the robot).

In 2019, the company started the year-long effort to pause and rebuild the technology so it could be deployed quickly to many customers with differing welding needs. The coronavirus pandemic delayed the launch by a few months, but also emphasized the glaring need for on-shoring of manufacturing, he said.

The AI also can be adapted for other industrial uses.

"We're not we're not really talking about it too much, but there will be a new product that's launched in the coming future, that will be another step into helping further propel manufacturing forward," Lonsberry said. "It's not going to be welding, but it's gonna be something very close and adjacent to welding."