When 3D printers hit the market around seven years ago, they were hailed as the next big thing. Tinkerers around the world used them to create everything from shoes to guns.

But with any new technology, there can be unforeseen issues, and 3D printers were no exception.

Enter New York-based R3 Printing, co-founded and led by Daniel Downs and Paul Sieradzki. Their company works to provide "3D printing that's safe, fast and completely automated" via their own printer, one they call "the next step in additive manufacturing."

"It was very clear that 3D printers have these huge problems and we’re going to be the guys that fix it."

But their journey to today's business model didn't begin with that same idea, although their first endeavor and their current one do have 3D printing in common.

“We got into [3D printing] because we are automotive aficionados, so we’re gear heads,” said Downs. “Paul is more of an Audi guy and I really like Porsche.”

The duo saw 3D printing as an opportunity to customize cars via the creation of one-off parts that are hard to find on older models, or elements that make a car lighter and faster.

So, they bought their first 3D printer in the fall of 2013, which led them down a rabbit hole of sorts, so much so that three years later, Downs left his job as a commercial real estate executive in Manhattan to establish a 3D printing manufacturing company. The goal was to produce goods for clients ranging from students to architects.

Not long after getting started, Downs and Sieradzki realized that their skill sets were not in line with what was necessary to run a manufacturing business. But all was not lost; they realized there was a need they could fill with what they'd learned.

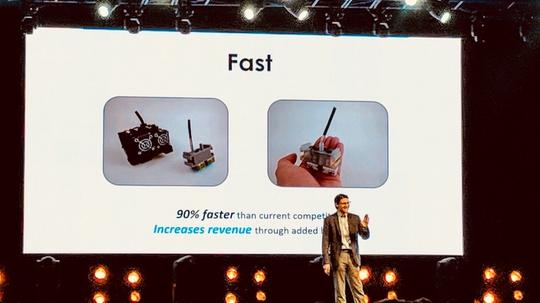

And that's what brought them to R3 Printing's mission: Creating a product without the common technical problems users of 3D printers encounter, such as injuries from moving components and printer slowness or inefficiency.

“This is the first generation of tech, and for the first generation of any tech it’s not going to be smooth,” Downs said. “It was very clear that 3D printers have these huge problems and we’re going to be the guys that fix it."

The R3 printer will reduce the need for workers to interact with the machine, which will reduce injury, according to Downs.

It will also increase speed and productivity, with the printer boasting a print rate that's 90 percent faster than competing products, as well as a 200 percent increase in build area.

These are stats that have caught others' attention, especially in Cincinnati. Downs and his team recently presented at the Ocean Accelerator IV Demo Day, with the event serving as the culmination of an experience that he found truly rewarding.

“It was a really good fit culturally,” Downs said, who added that his values aligned well with the faith-based focus of the accelerator. “We applied to Ocean and hopped on the phone with Scott [Weiss, chairman of the board], Lauren [Tiffan, program director] and Tim [Metzner, co-founder] and, very clearly, the synergy was there from moment one.”

The R3 Printing team and its mission has resonated with others, too; the company has raised $51,000 since Demo Day via crowdfunding. They will also pitch at Technori in Chicago on May 29.

As for their product, they have fifty percent of their beta testing completed, and plan to launch the initial product in March of 2019.