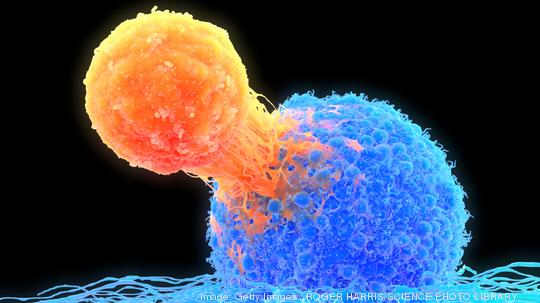

Founded three years ago in Acton, with the mission to advance the use of biomaterials to make human tissue for research, FluidForm has just entered an agreement with Ethicon, a member of the Johnson & Johnson Medical Devices Cos.

The company has been working with Ethicon since last year, using its technology to recreate the properties of tissue in a lab setting. Its technology has been able to build beating heart chamber, valves and even blood vessels that operate as a fully functional heart.

FluidForm’s team of 12 hopes to someday build a full-sized human organ to scale.

“Technology like this is in place to help save people's lives and repair damaged organs, with the goal of ultimately replacing organs,” CEO Mike Graffeo said.

Graffeo breaking the company's goals down into the need to do four things well: One, work with the very same materials that exist in the human body; two, work in a similar way as the body when it assembles tissues; three, be able to demonstrate how it works; and four, build an organ to scale.

“With each of those things, we're kind of the best in the industry," he said. "That’s what differentiates us from our competitors."

FluidForm’s data reports that there are about 130,000 people on the nation’s organ transplant waiting list, but the company claims that the need for organs is actually about 10 times that size. Meanwhile, only about 30,000 of them will get one this year.

Graffeo said he wants FluidForm’s technology to get to a point where it's readily available in hospitals. But there are many stepping stones before then.

“Compare it to a company like SpaceX that wants to get to Mars. But in order to get to Mars, they had to start by putting satellites into orbit, and then by taking astronauts to the space station. They first reached the moon, and then they finally got to Mars. Those building blocks had to be there,” Graffeo said.

The company is still working on its sales and distribution model, depending on when the company is able to develop full-term tissue and organs and how it will get its products into hospitals.

“Some of those products that we develop would be best sold by us, some of those products we develop might be best sold by a partner,”Graffeo said.

Mass. tech and biotech IPOs in the first half of 2021

Company: Cambridge-based Cullinan Oncology Inc. (Nasdaq: CGEM)

IPO date: January 8, 2021

Stock performance since IPO: Down

Pictured: Owen Hughes (left), CEO of Cullinan Oncology, and co-founder Patrick Baeuerle

Courtesy photo

Company: Burlington-based Agrify Corp. (Nasdaq: AGFY)

IPO date: January 28, 2021

Stock performance since IPO: Level

Pictured: A photo from the 2019 Marijuana Business Conference and Cannabis Expo ("MJBiz Con"), a trade show where Agrify was a platinum sponsor

Agrify

Company: Cambridge-based Vor Biopharma Inc. (Nasdaq: VOR)

IPO date: February 5, 2021

Stock performance since IPO: Down

Pictured: Vor Biopharma co-founder Siddhartha Mukherjee

Deborah Feingold photography

Company: Boston-based Decibel Therapeutics Inc. (Nasdaq: DBTX)

IPO date: February 12, 2021

Stock performance since IPO: Down

Pictured: Laurence Reid, CEO of Decibel Therapeutics, was chief business officer of Alnylam Pharmaceuticals

Courtesy Alnylam

Company: Somerville-based Finch Therapeutics Inc. (Nasdaq: FNCH)

IPO date: March 19, 2021

Stock performance since IPO: Down

Pictured: Finch Therapeutics CEO Mark Smith

Finch Therapeutics

Company: Boston-based Semrush Holdings Inc. (NYSE: SEMR)

IPO date: March 25, 2021

Stock performance since IPO: Up

Pictured: Eugene Levin, chief strategy officer at Semrush

Semrush Holdings Inc.

Company: Marlborough-based Akoya Biosciences Inc. (Nasdaq: AKYA)

IPO date: April 16, 2021

Stock performance since IPO: Up

Pictured: Brian McKelligon, CEO of Akoya Biosciences

Akoya Biosciences Inc.

Company: Cambridge-based Werewolf Therapeutics Inc. (Nasdaq: HOWL)

IPO date: April 30, 2021

Stock performance since IPO: Level

Pictured: Werewolf Therapeutics CEO Dan Hicklin began developing Werewolf Therapeutics while overseeing Potenza Therapeutics, acquired by Astellas Pharma last year

Courtesy photo

Company: Boston-based Flywire Corp. (Nasdaq: FLYW)

IPO date: May 26, 2021

Stock performance since IPO: Level

Pictured: Mike Massaro, CEO of Flywire

Brent Mills

Company: Cambridge-based Verve Therapeutics Inc. (Nasdaq: VERV)

IPO date: June 17, 2021

Stock performance since IPO: Up

Pictured: Sekar Kathiresan, CEO of Verve Therapeutics

Verve Therapeutics

Company: Lexington-based Cyteir Therapeutics Inc. (Nasdaq: CYT)

IPO date: June 18, 2021

Stock performance since IPO: Up

Pictured: Markus Renschler, CEO of Cyteir Therapeutics

Cyteir Therapeutics

Company: Boston-based Monte Rosa Therapeutics Inc. (Nasdaq: GLUE)

IPO date: June 24, 2021

Stock performance since IPO: Level

Pictured: Monte Rosa Therapeutics CEO Markus Warmuth previously worked at Third Rock Ventures and Novartis AG

Courtesy photo

Company: Boston-based Aerovate Therapeutics Inc. (Nasdaq: AVTE)

IPO date: June 30, 2021

Stock performance since IPO: Up

Pictured: Timothy Noyes, CEO of Aerovate Therapeutics

Aerovate Therapeutics Inc.